Buy these AFM Probes together with other BudgetSensors AFM probes of your choice in a Budget Combo Box!

Buy these AFM Probes together with other BudgetSensors AFM probes of your choice in a Budget Combo Box!

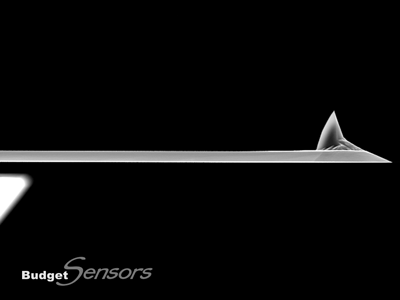

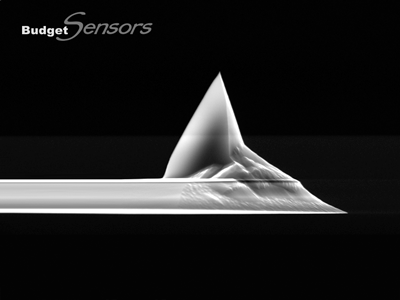

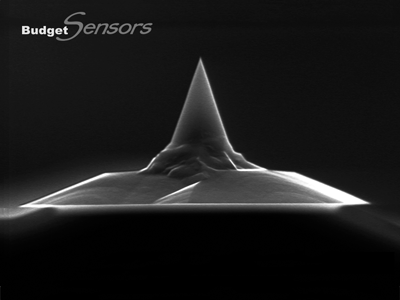

Micromachined monolithic silicon AFM probe for high frequency non-contact and tapping mode operation.

The consistent AFM tip radius of less than 10 nm ensures high resolution and good reproducibility. The rotated AFM tip provides more symmetric representation of high sample features.

The AFM probe features a reflective aluminum coating on the back side of the AFM cantilever. For measurements in liquids please use the back side gold coated Tap300GD-G or the overall gold coated Tap300GB-G!

With its industry standard dimensions of 3.4 x 1.6 x 0.3 mm the holder chip fits most commercial AFM systems.

Consistent high quality at a lower price!

This AFM probe features alignment grooves on the back side of the holder chip.

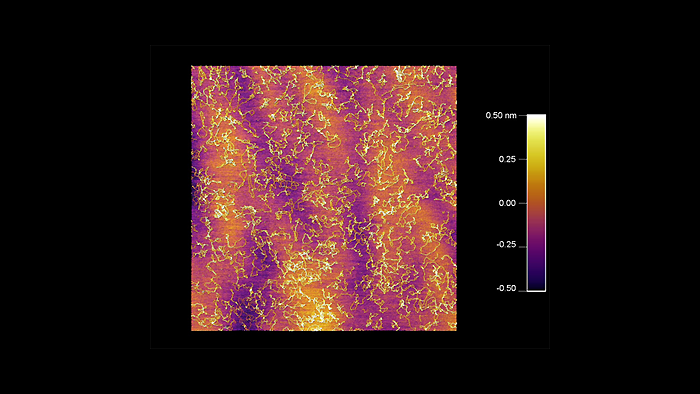

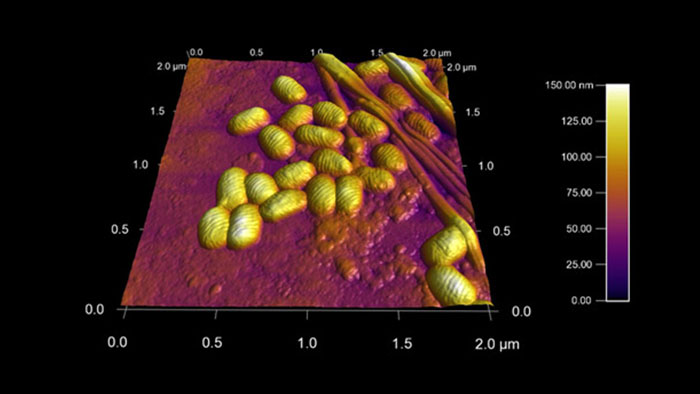

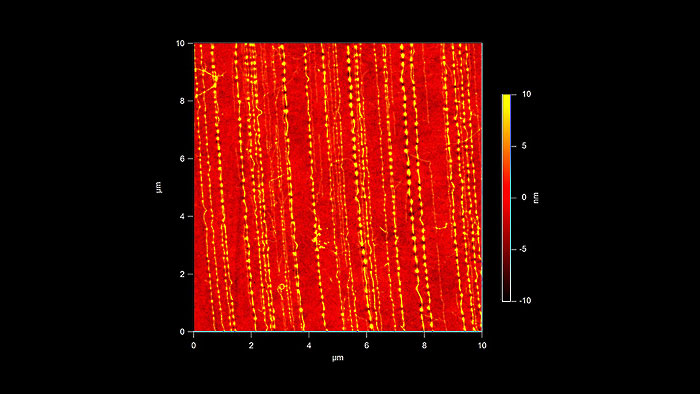

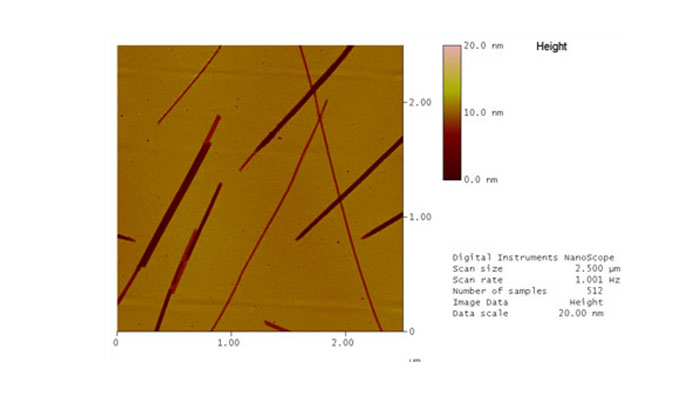

Topography image of dried DNA

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 5 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

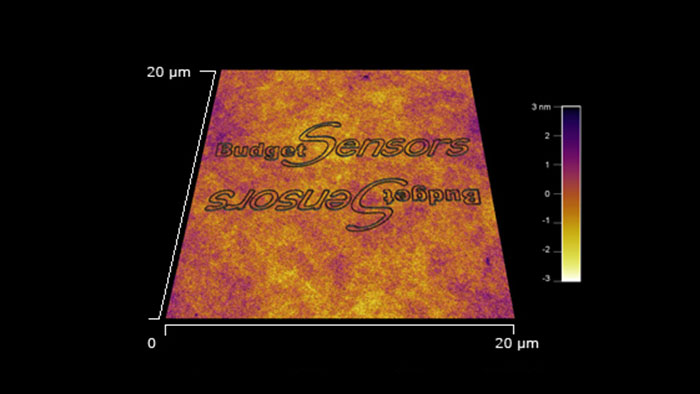

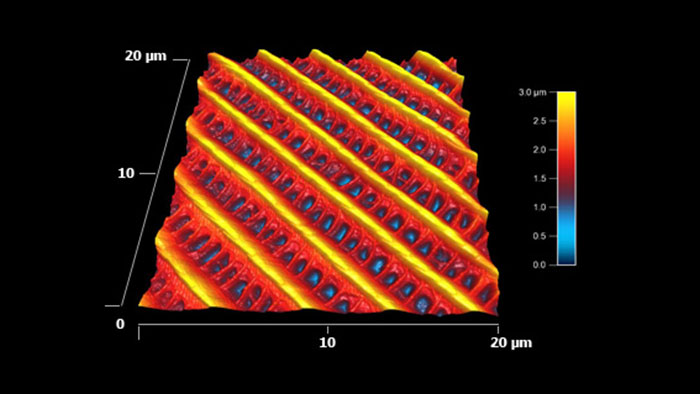

The BudgetSensors logo imprinted by scratch lithography on a flame annealed polycarbonate surface with a BudgetSensors Tap300Al-G AFM probe and an Asylum MFP 3D AFM system

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum MFP 3D AFM system, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

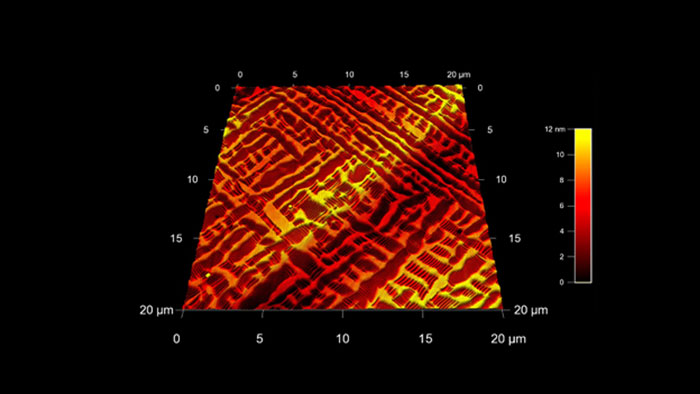

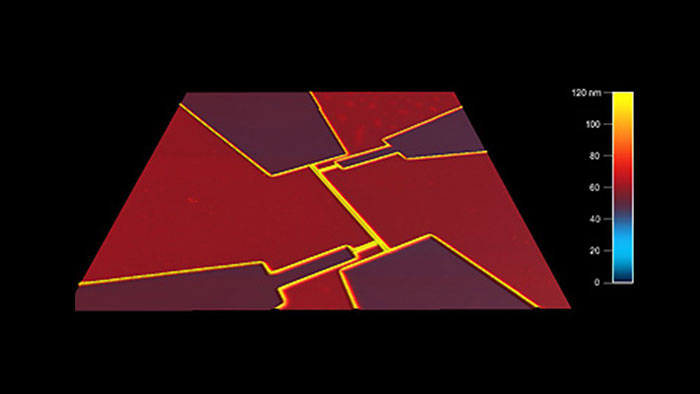

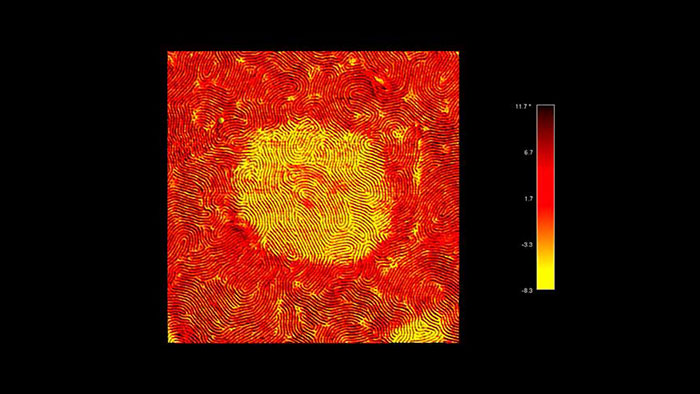

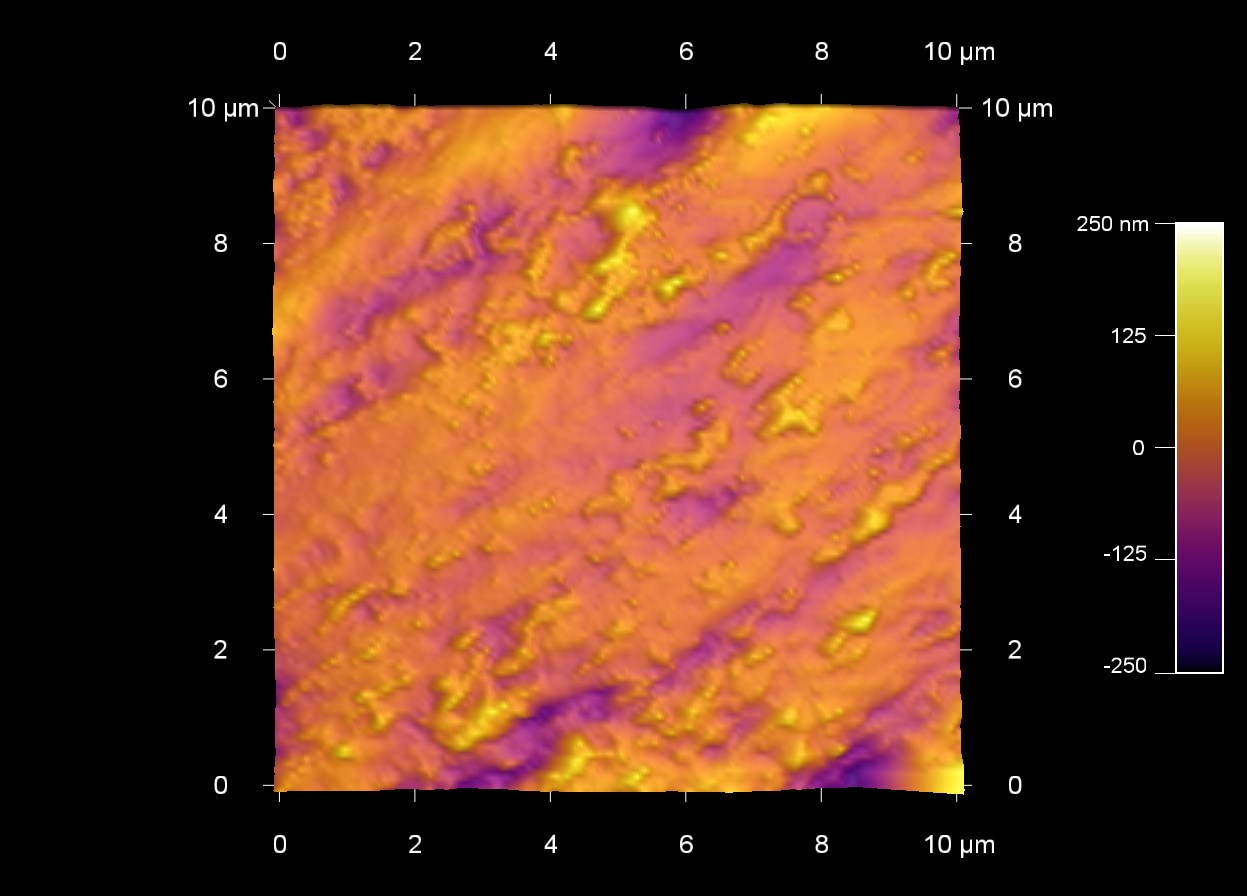

Bismuth iron oxide (BFO) thin film on lanthanum aluminate (LAO)

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 4 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe and an Asylum MFP 3D AFM system, 2 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

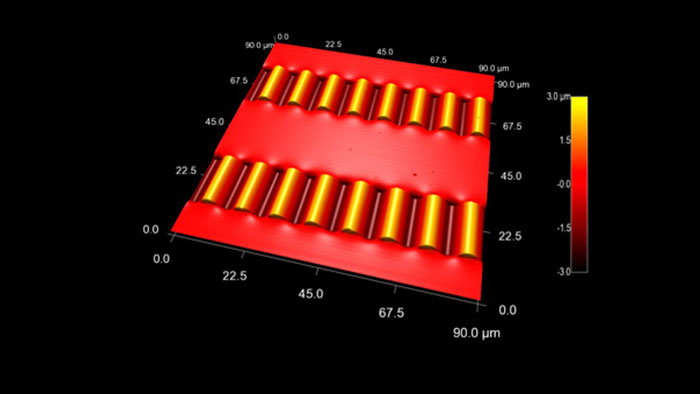

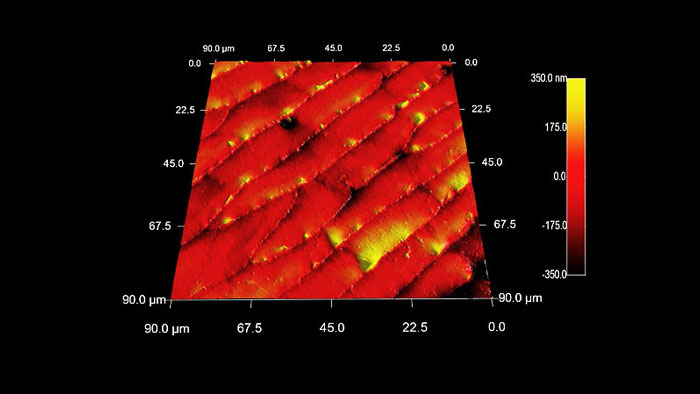

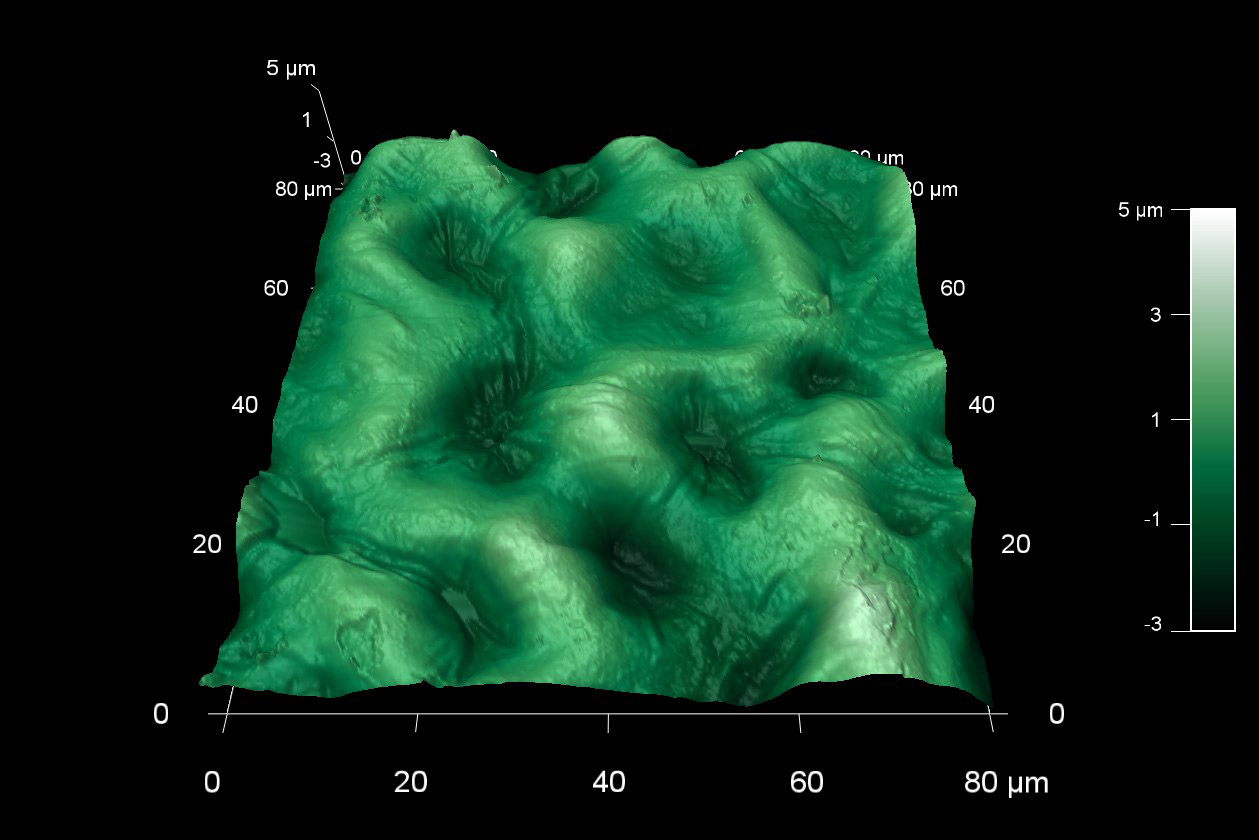

Compressed silicon nanoribbons on a flexible PDMS substrate

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum MFP-3D AFM system, 90 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

A superconducting quantum photon detecting device

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum MFP-3D AFM system, 25 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

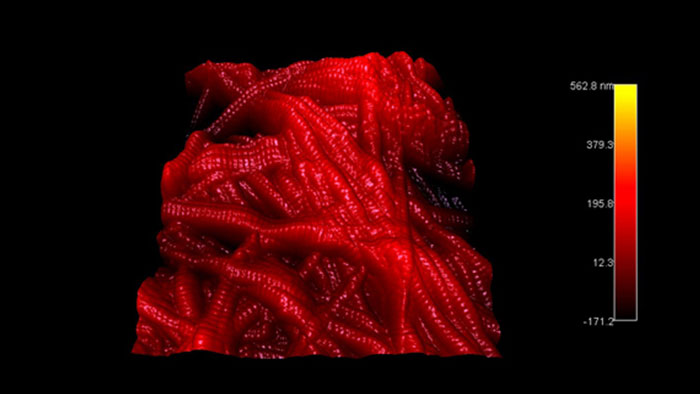

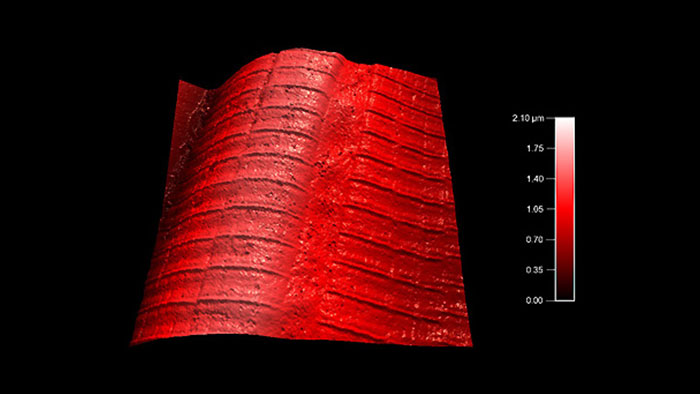

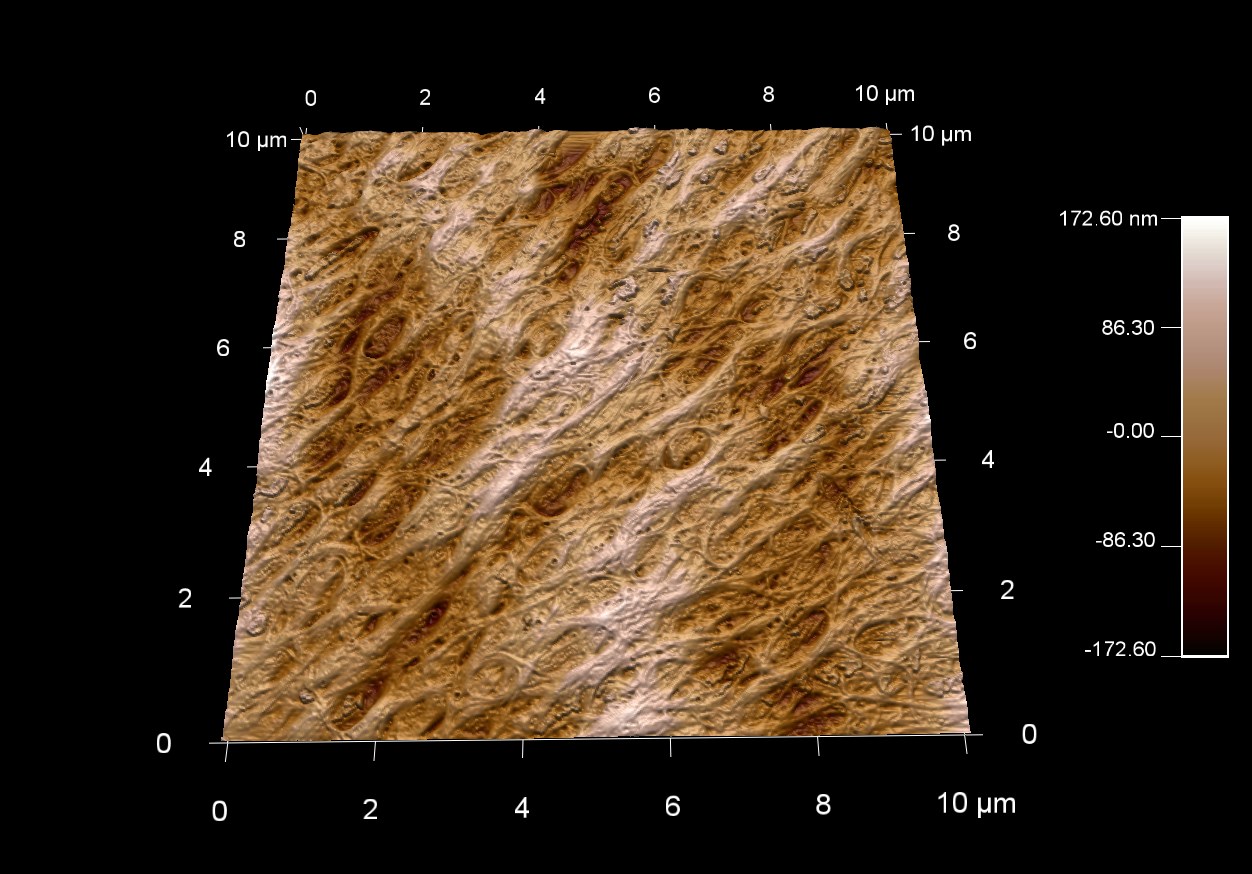

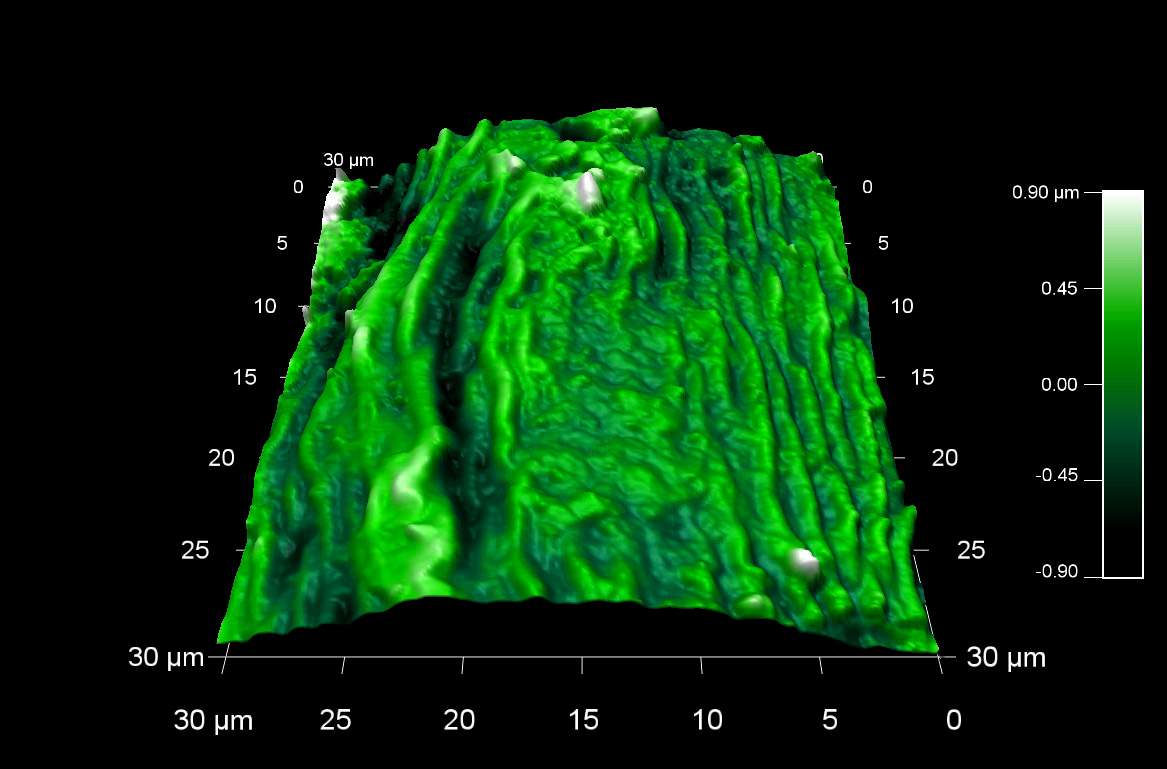

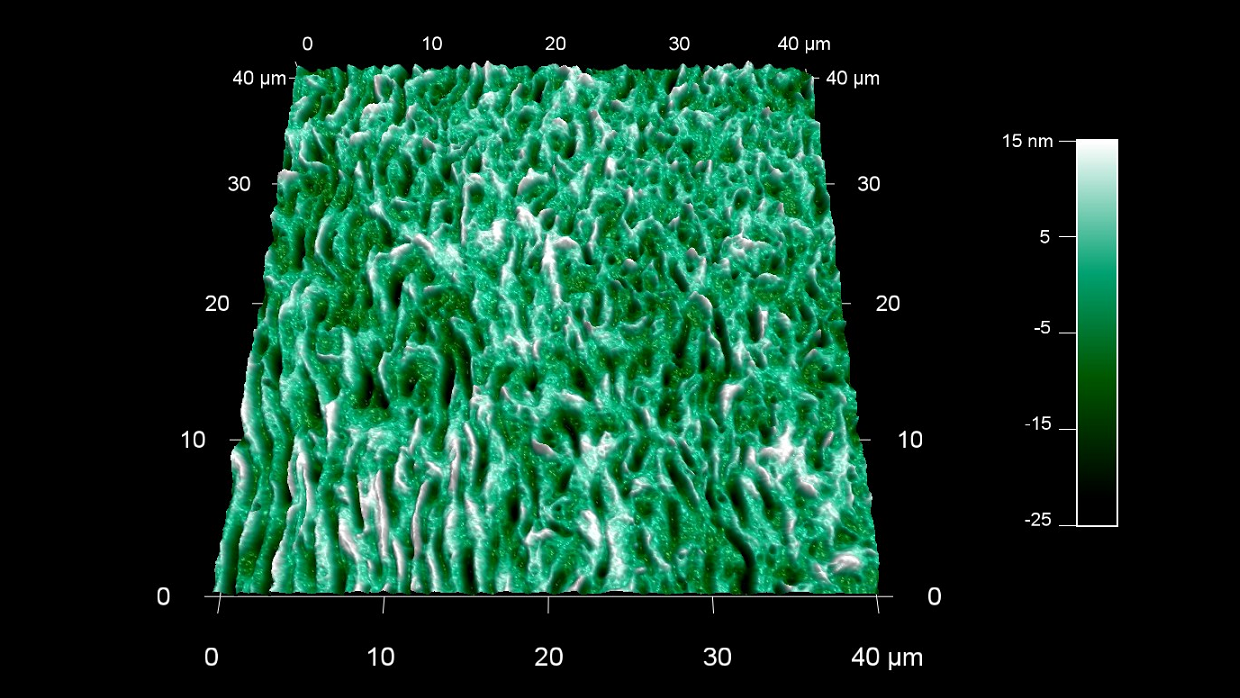

Mouse skeletal muscle fiber

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum MFP-3D AFM system, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

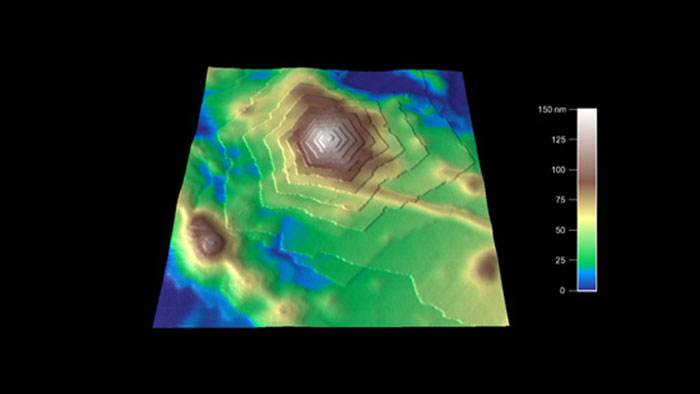

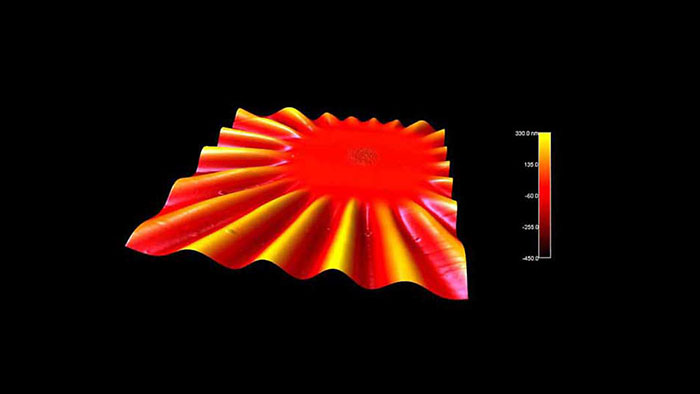

A screw dislocation in a polymer surface

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum MFP-3D AFM system, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

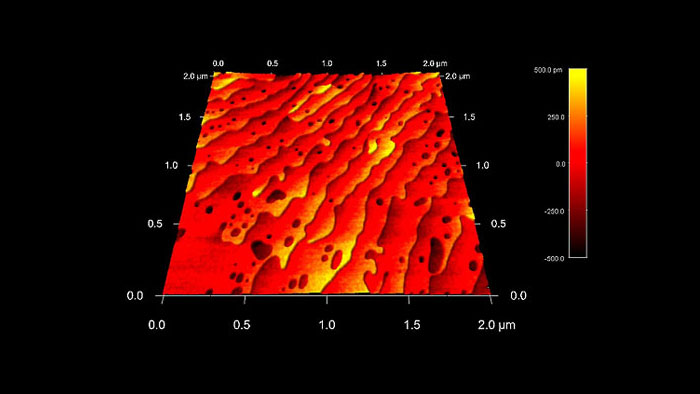

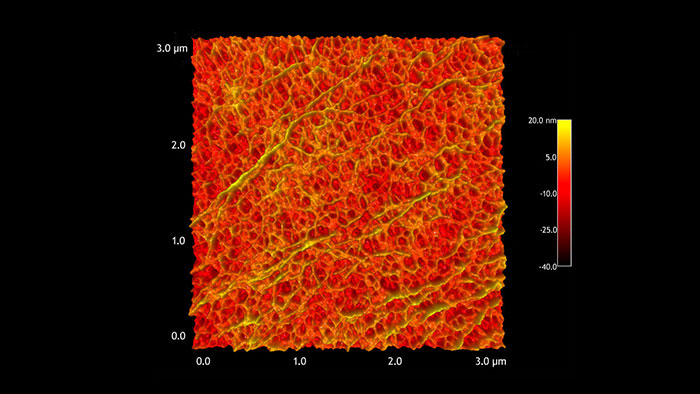

A crack in a nitride thin film

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 2 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

A gypsum crystal etched with water

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

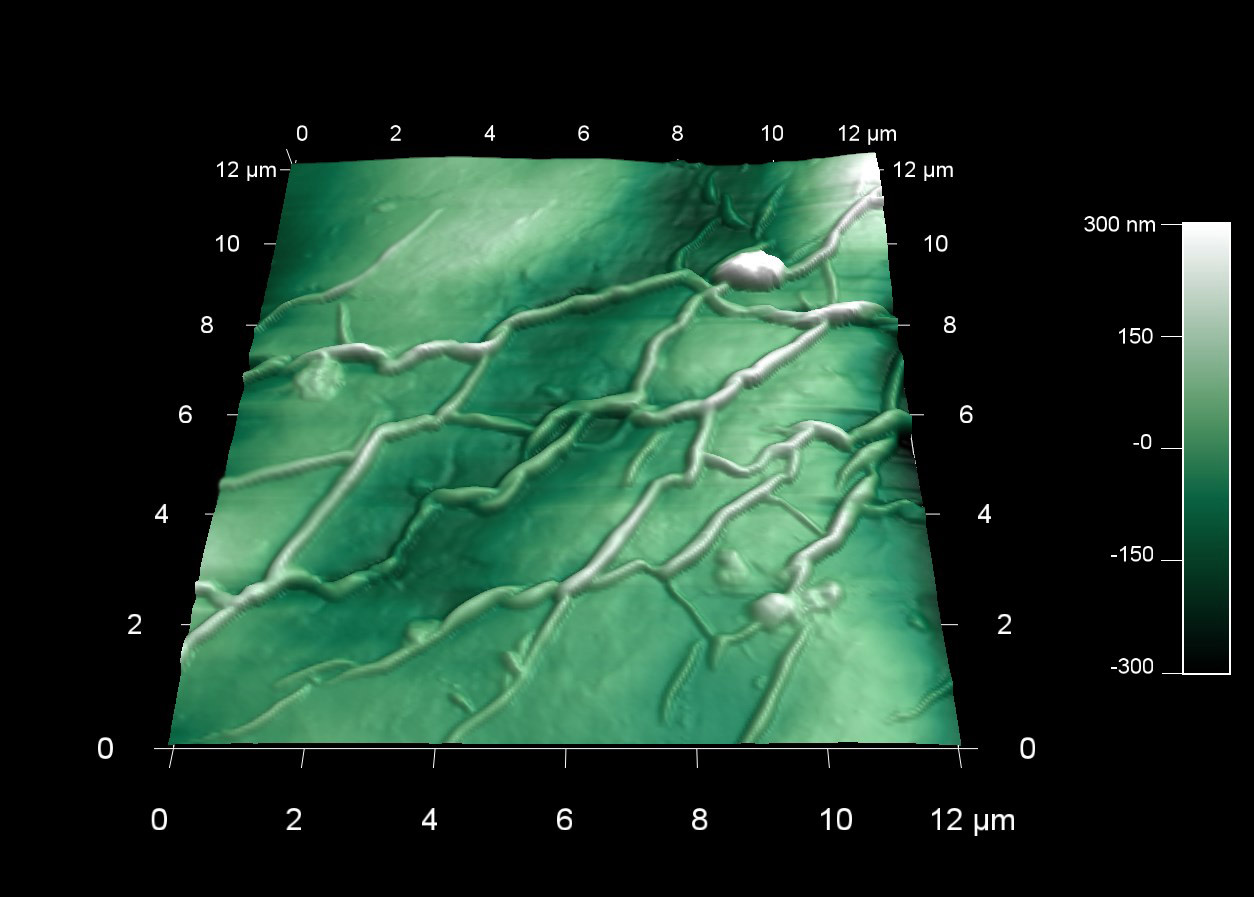

Carbon nanotubes and bundles on quartz atomic steps

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Cypher AFM system, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Topography image of the wing of a moth. The nanostructure makes the wing highly hydrophobic and it's directional - water droplets will only flow away from the body off the ends of the wing, keeping the body dry.

Scanned with a BudgetSensors Tap300Al-G AFM probe on an Asylum Research MFP-3D AFM system, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

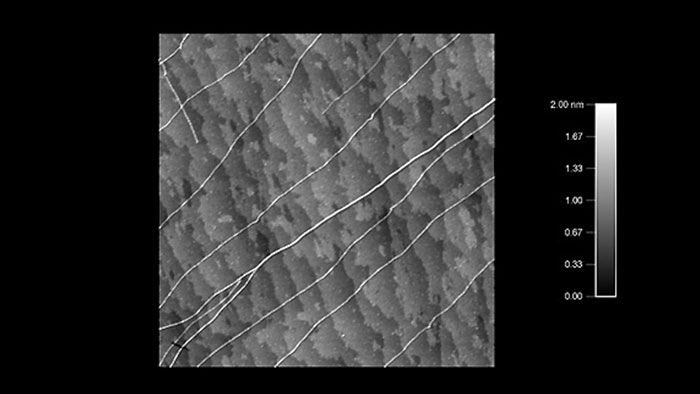

Single wall carbon nanotubes are transferred to an elastic PDMS substrate, then laterally compressed, causing the nanotubes to buckle into waves.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 10 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

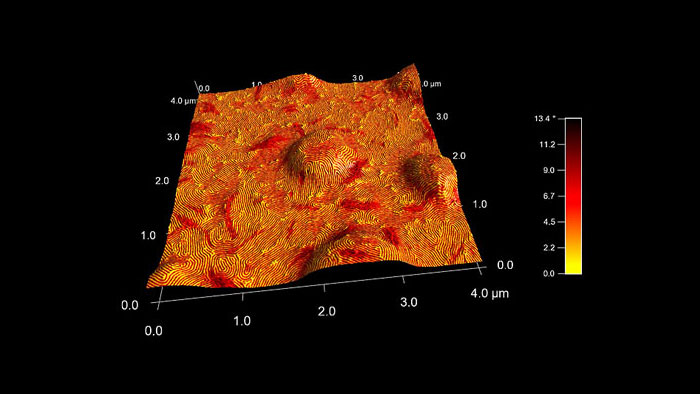

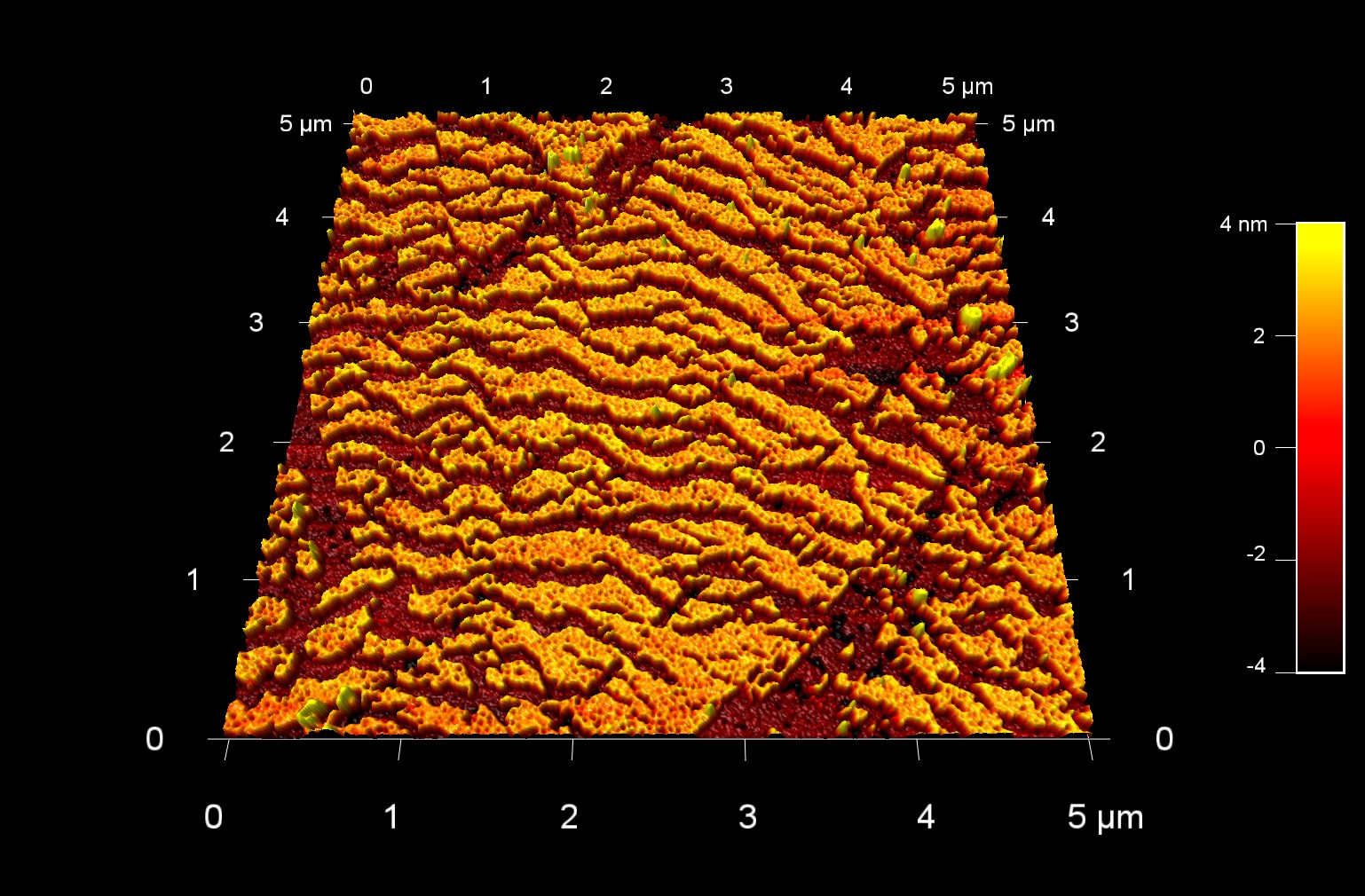

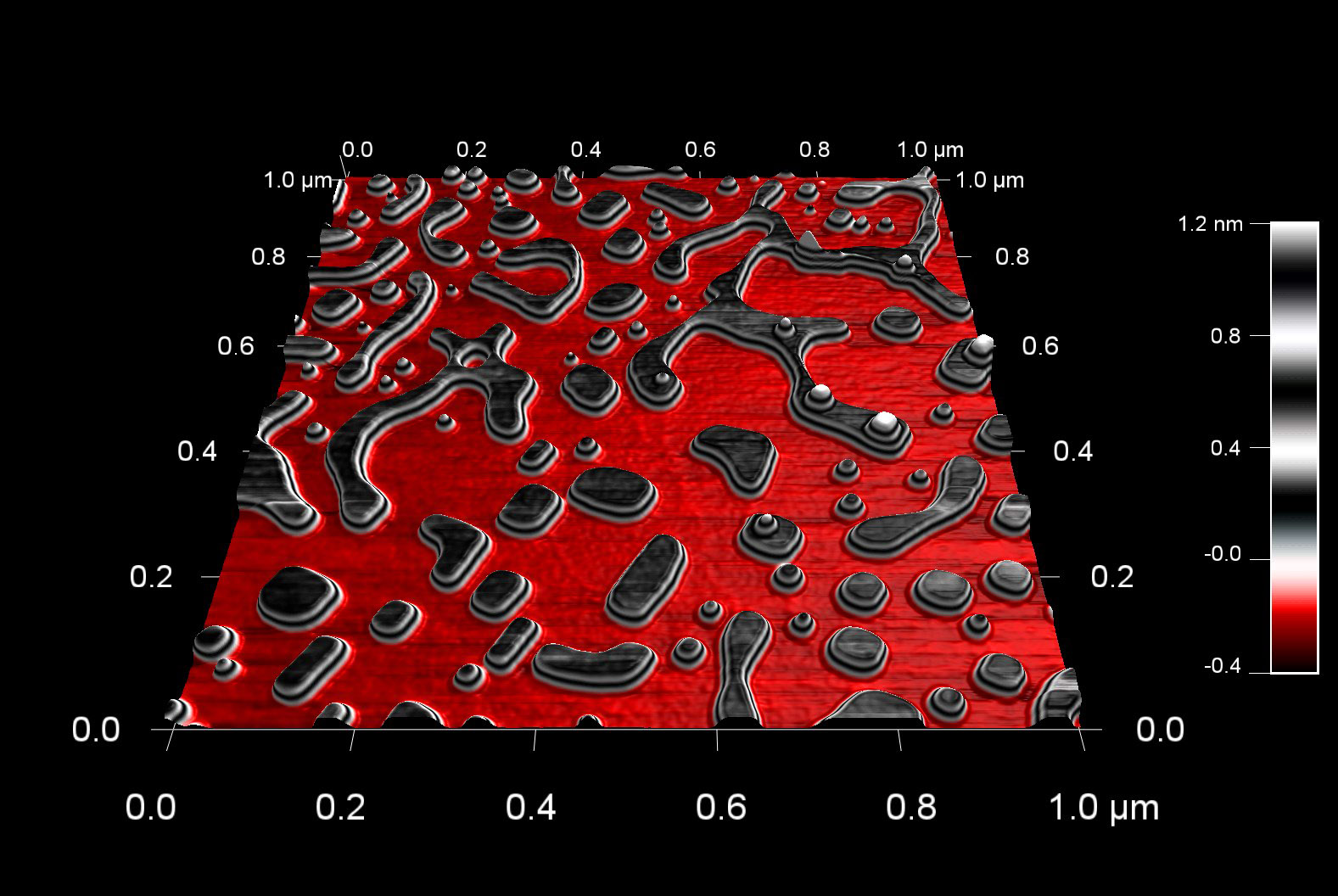

Phase image of a SEBS block copolymer, topography rendered in 3D, overlaid with the color data from the phase image

Scanned with a BudgetSensors Tap300Al-G AFM probe, 4 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

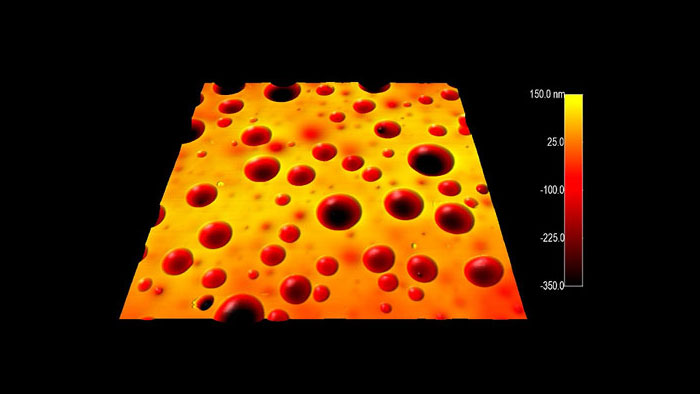

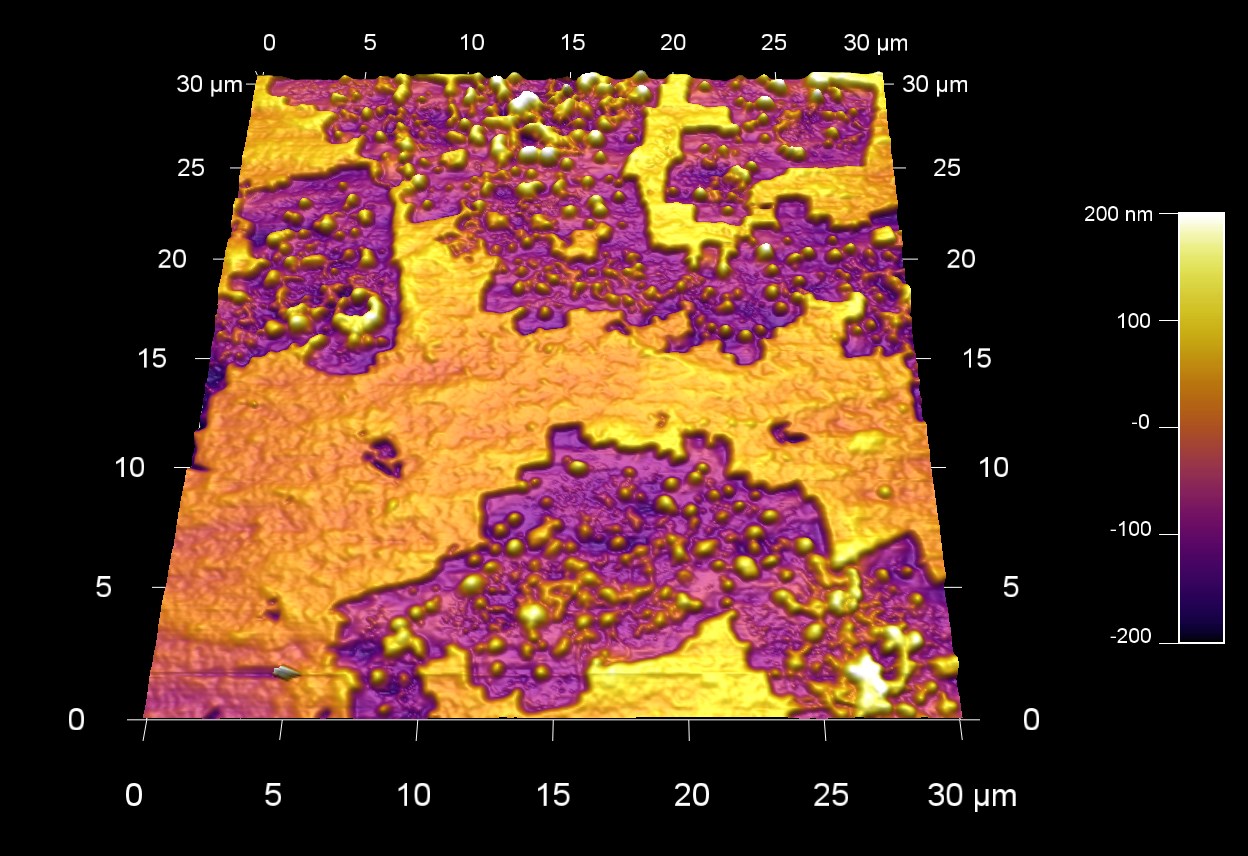

Thin film of Zein protein with cholesterol

Scanned with a BudgetSensors Tap300Al-G AFM probe, 15 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

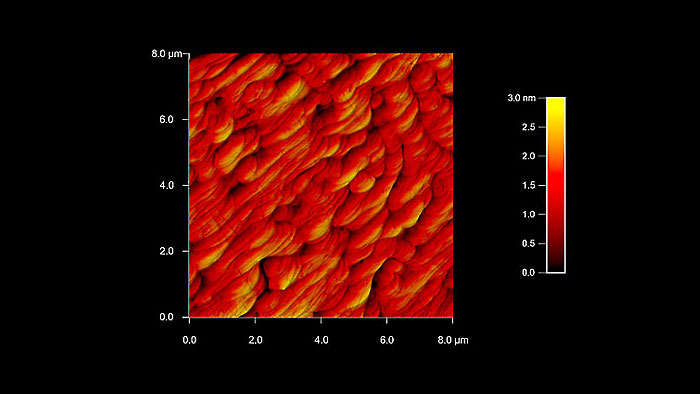

Atomic steps on a palladium surface

Scanned with a BudgetSensors Tap300Al-G AFM probe, 8 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

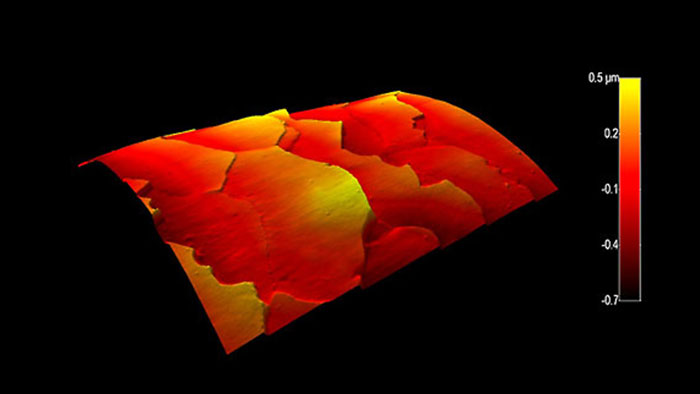

The curved surface of a human hair

Scanned with a BudgetSensors Tap300Al-G AFM probe, 35 micron scan tsize

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

The surface of an ant's abdominal plating

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

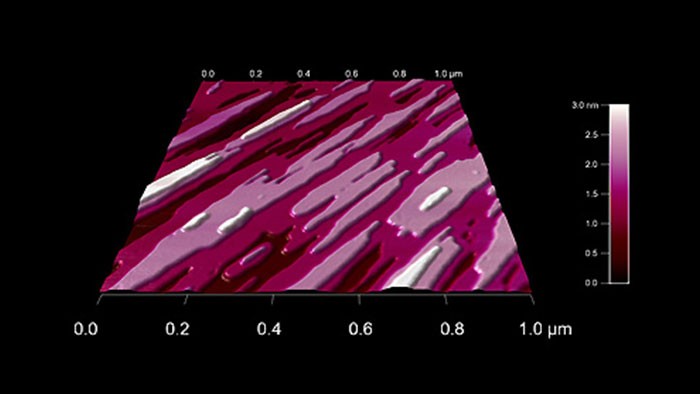

Strontium titanium oxide (SrTiO3) surface with 4 Angstrom steps

Scanned with a BudgetSensors Tap300Al-G AFM probe, 2 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

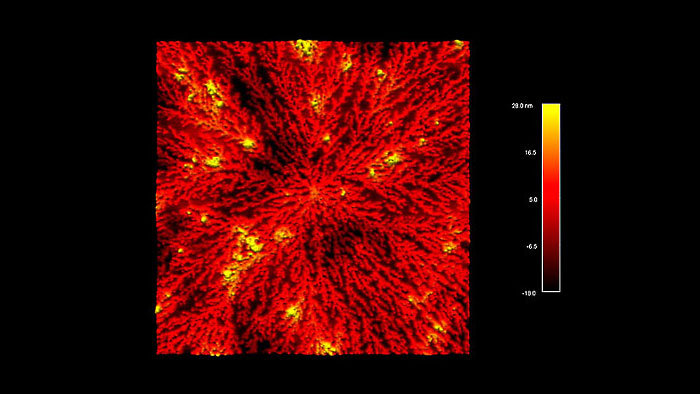

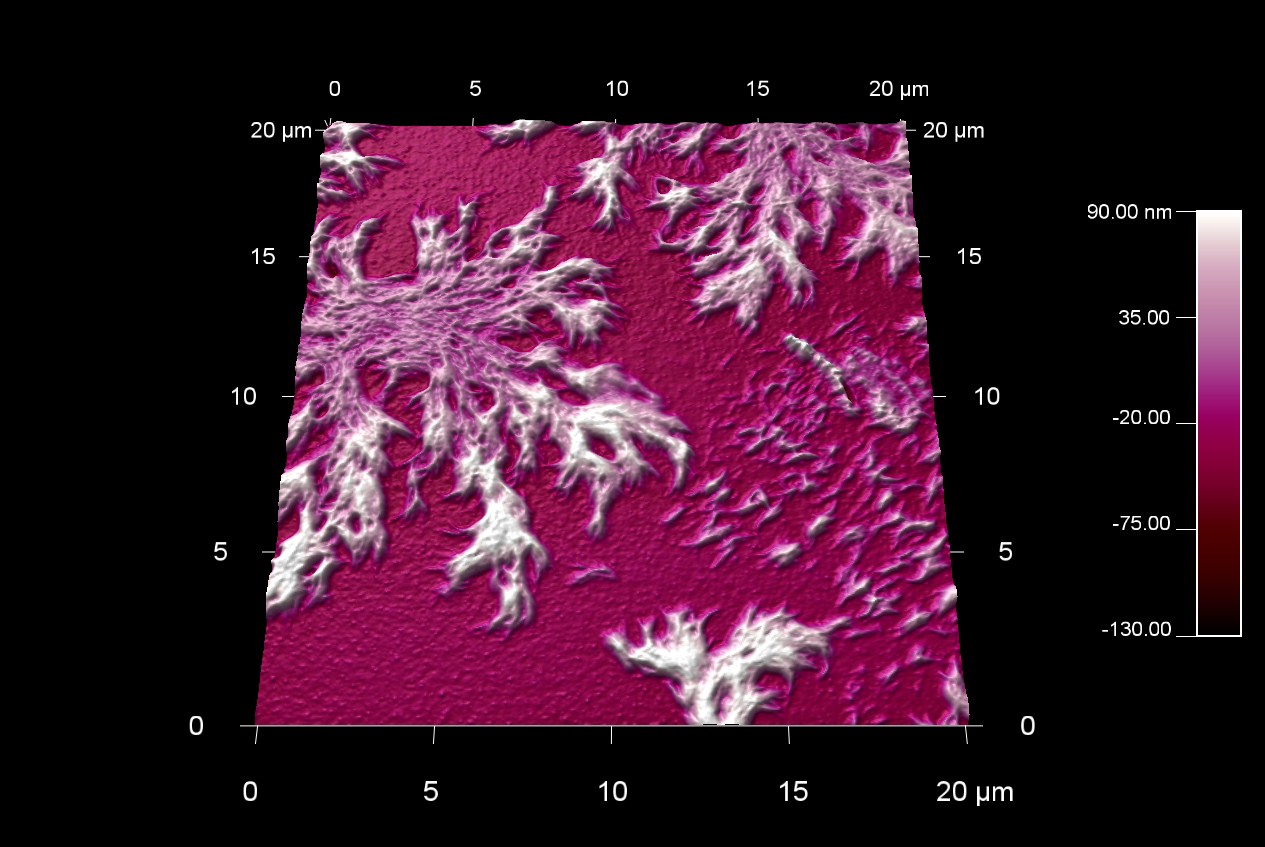

Dendritic growth of platinum nanoclusters

Scanned with a BudgetSensors Tap300Al-G AFM probe, 7 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

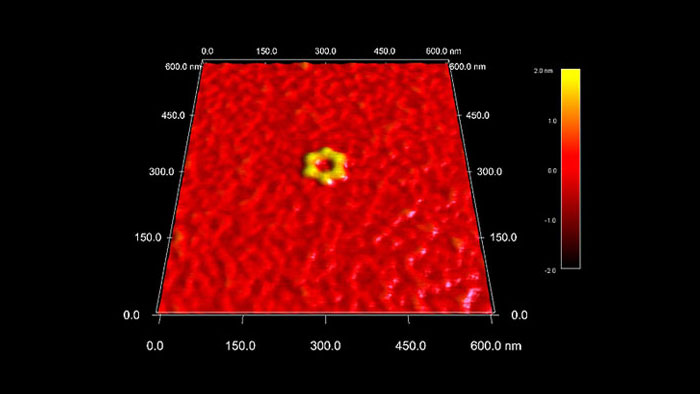

Hexagonal DNA nanostructure

Scanned with a BudgetSensors Tap300Al-G AFM probe, 600 nanometer scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

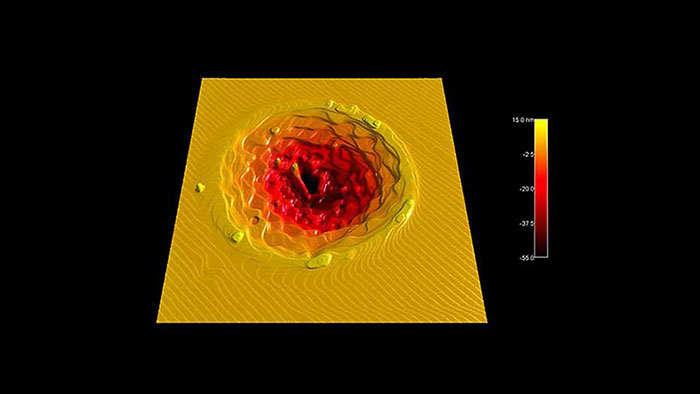

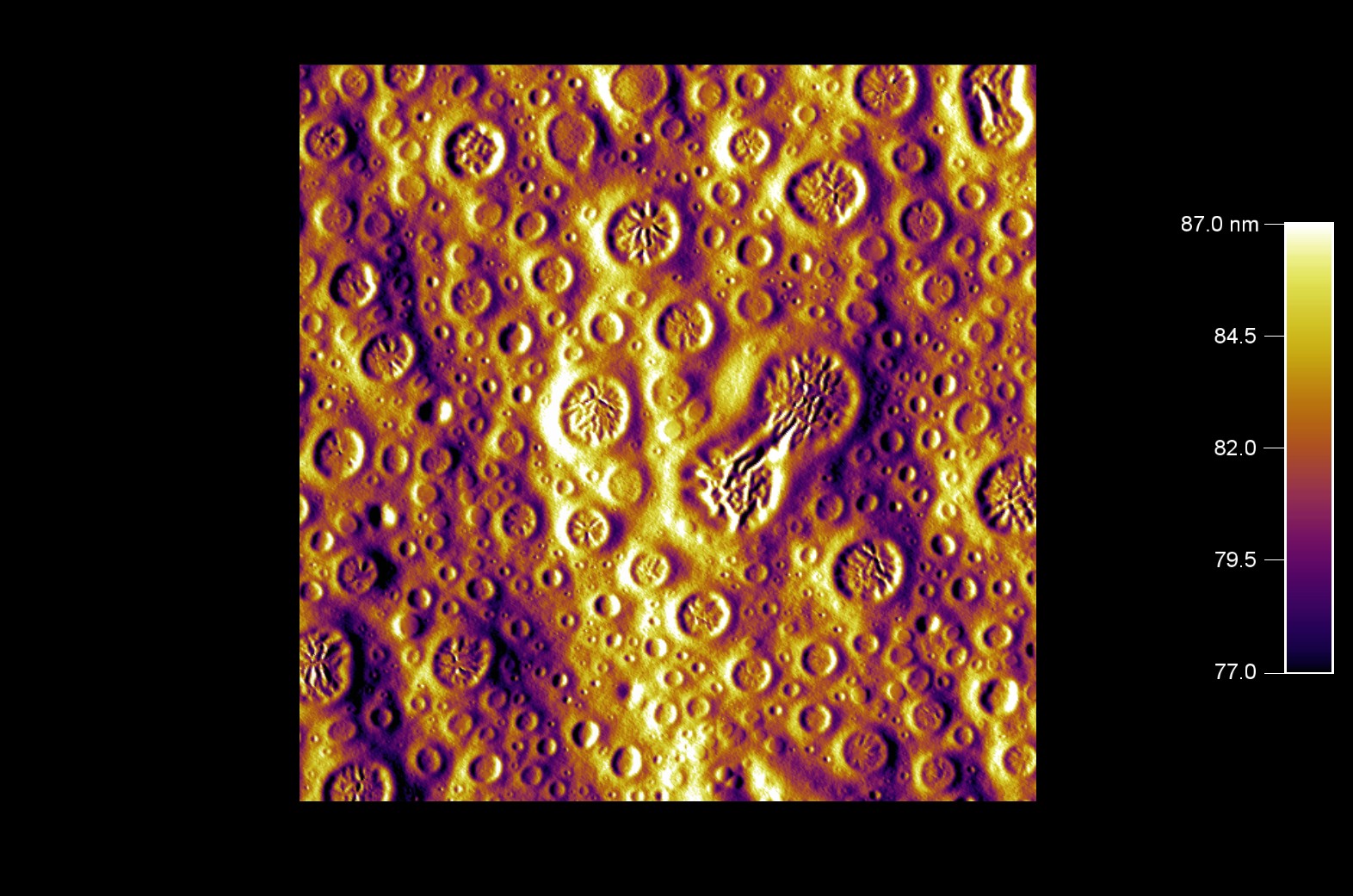

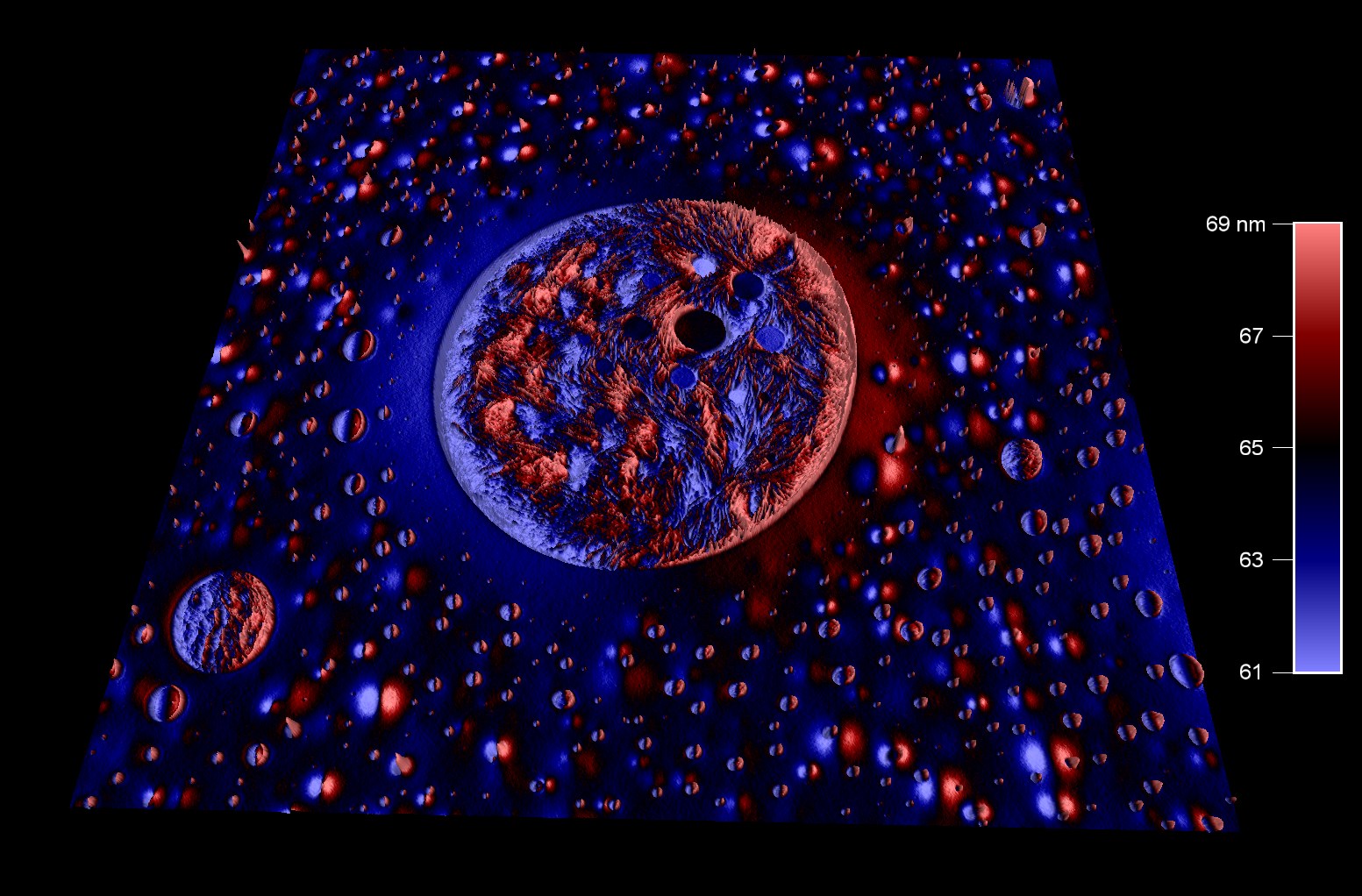

Silicon surface impacted with molten copper droplet from the exhaust of a spacecraft ion thruster

Scanned with a BudgetSensors Tap300Al-G AFM probe, 25 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

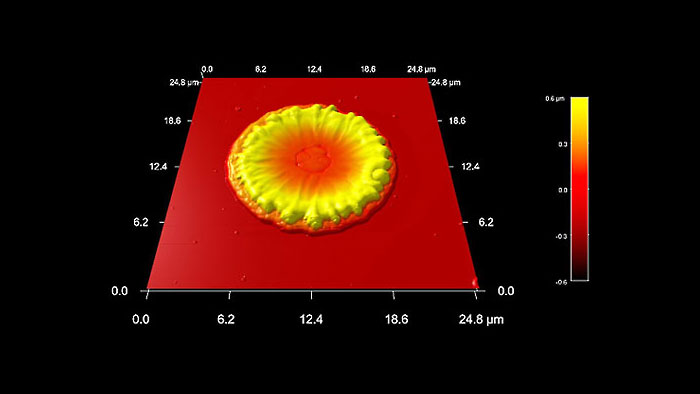

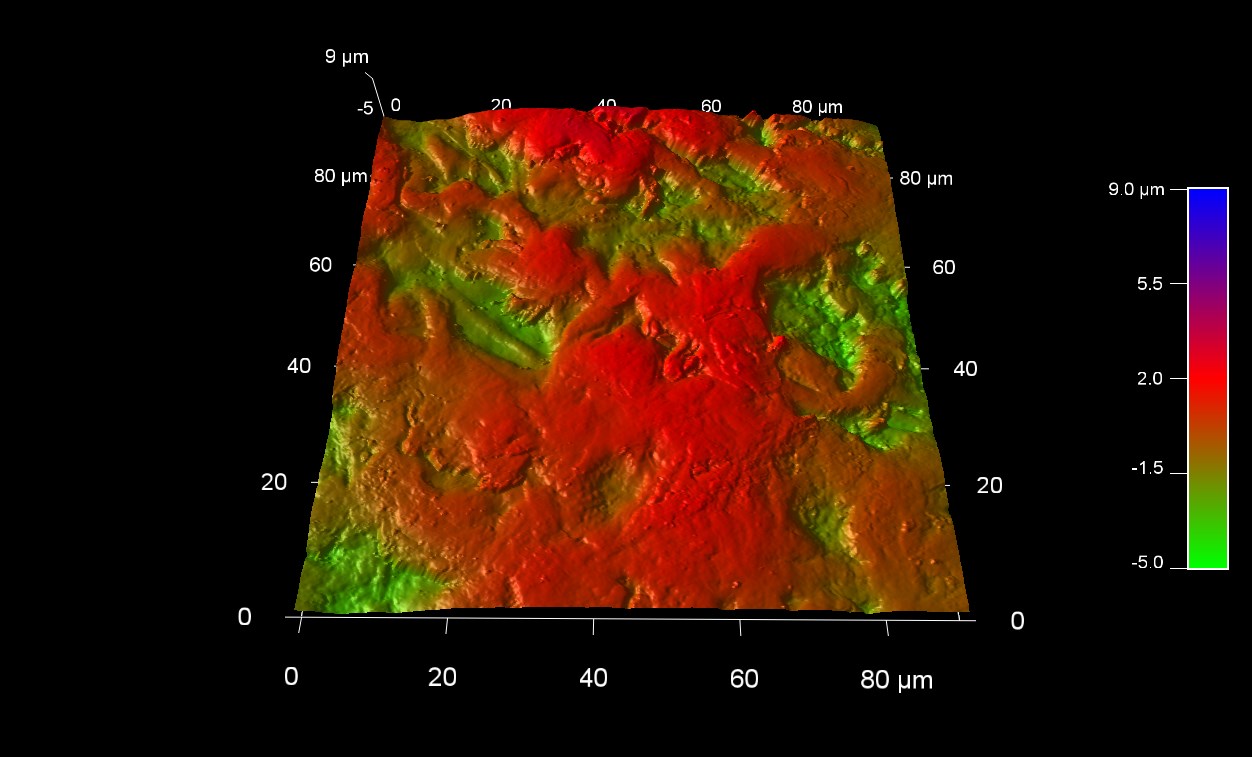

Crater in a sapphire substrate hit with a femtosecond laser pulse, followed by annealing to develop the step structure. The top surface is covered with single atomic steps (3Å).

Scanned with a BudgetSensors Tap300Al-G AFM probe, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

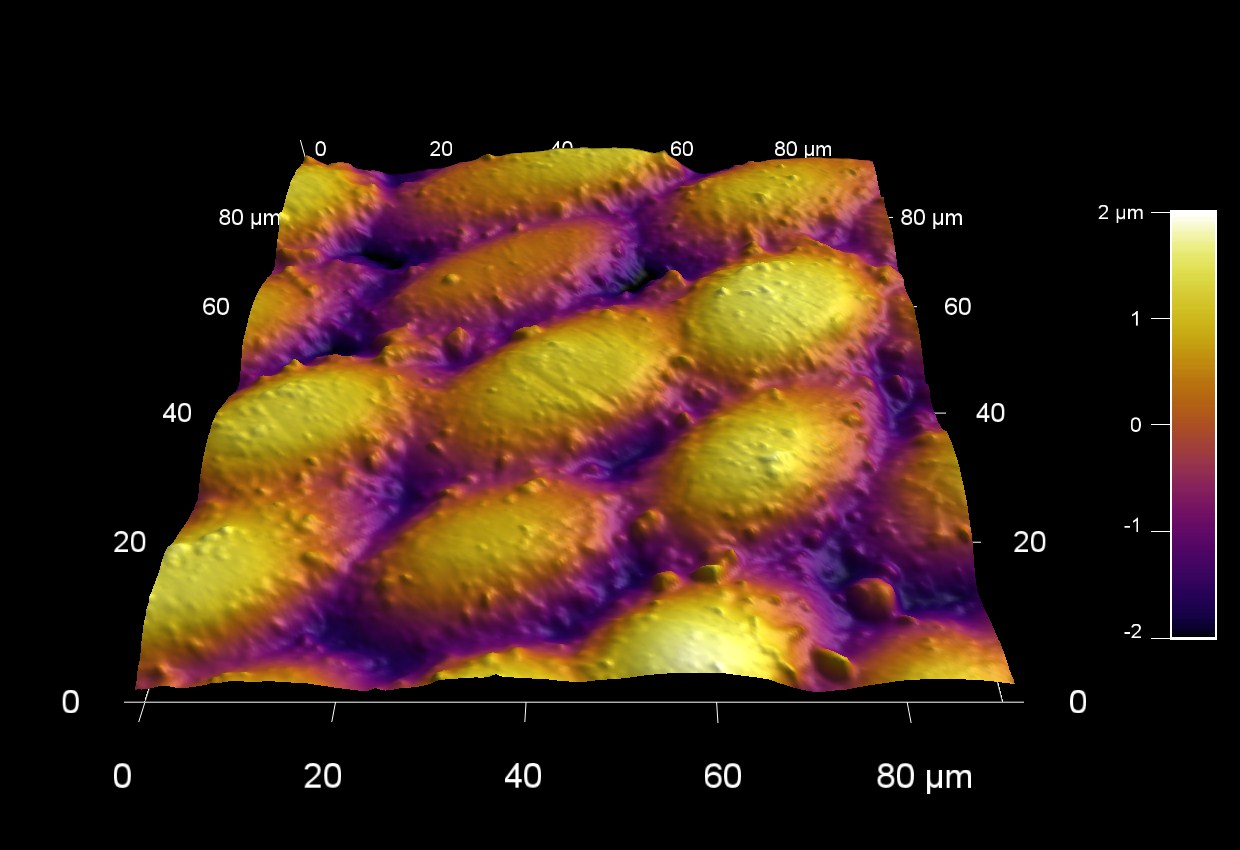

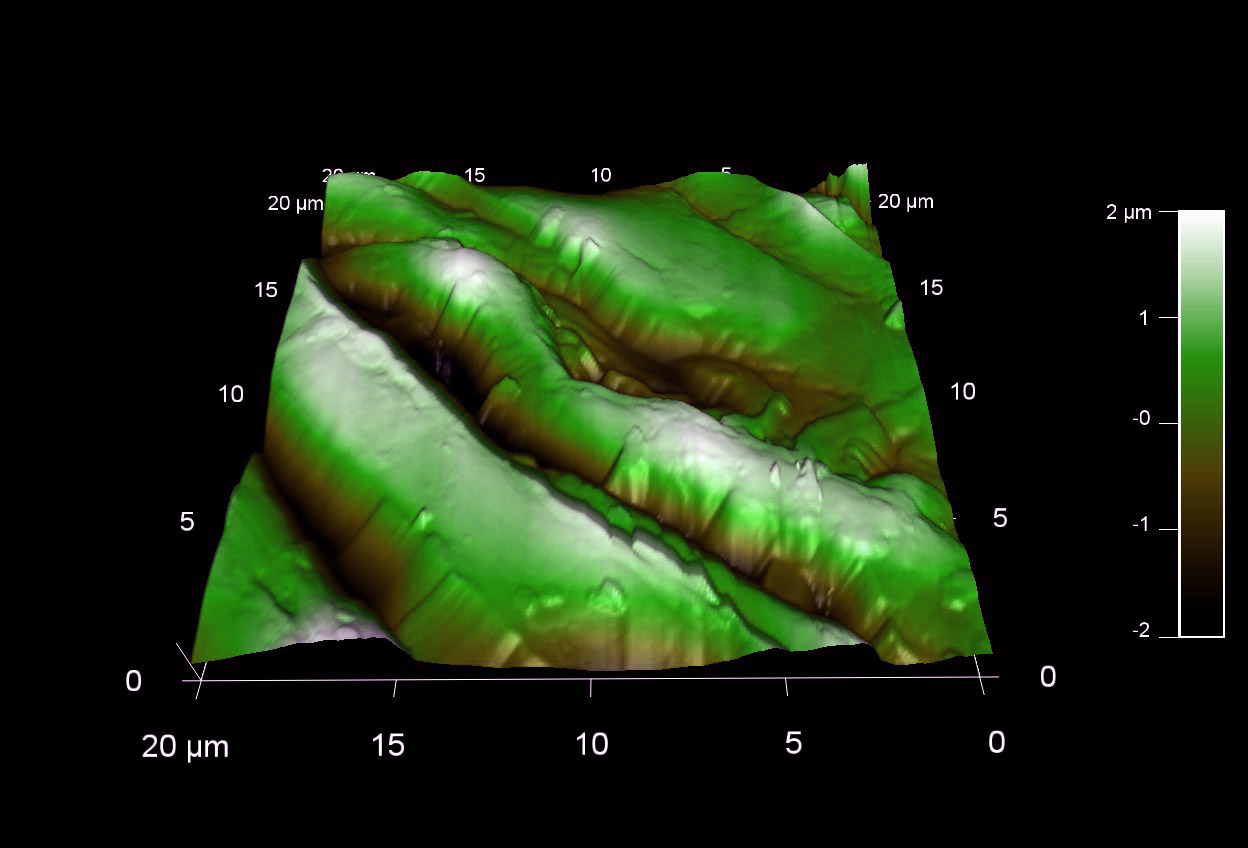

An extremely thin (30 nm) free standing silicon nitride membrane with nickel nanoparticles, following heating with a short laser pulse. The nanoparticles react with the substrate, and the induced stress in the film creates large ripples in the membrane surface

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Finely detailed surface of biaxially-oriented polypropylene (BOPP)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Magnesium oxide (MgO) crystal, carved in a Focused Ion Beam (FIB) system. The top, unaltered surface shows single and double atomic steps.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 20 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Crystallization of poly(benzyl-beta-L-glutamate) on glass

Scanned with a BudgetSensors Tap300Al-G AFM probe, 30 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

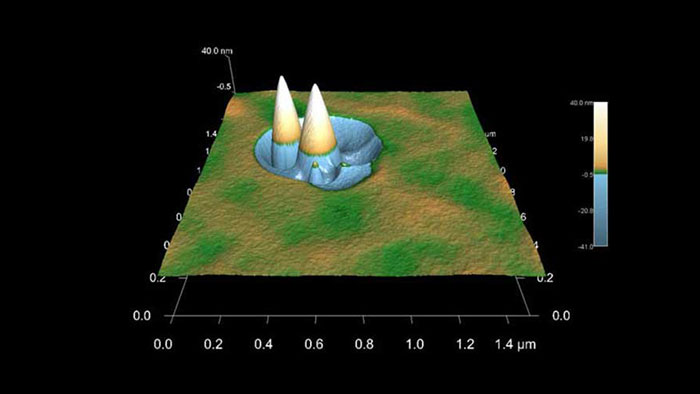

Contaminants on the surface prior to sputtering give rise to classic sputter cone formation.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1.5 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

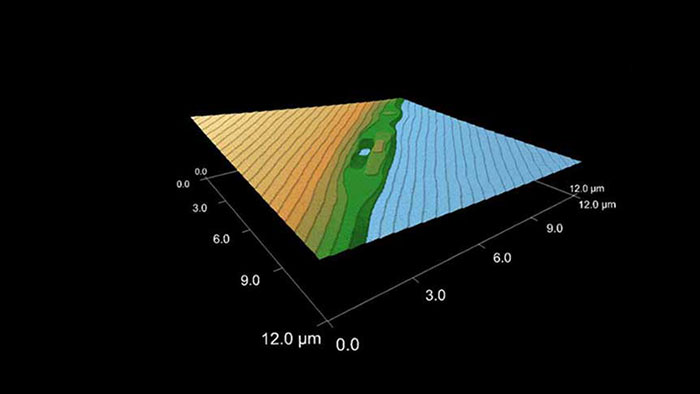

Sapphire crystal following annealing at 1400°C, leaving a clean surface with atomic steps and occasional defects. The steps are approximately 3Å tall.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 12 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

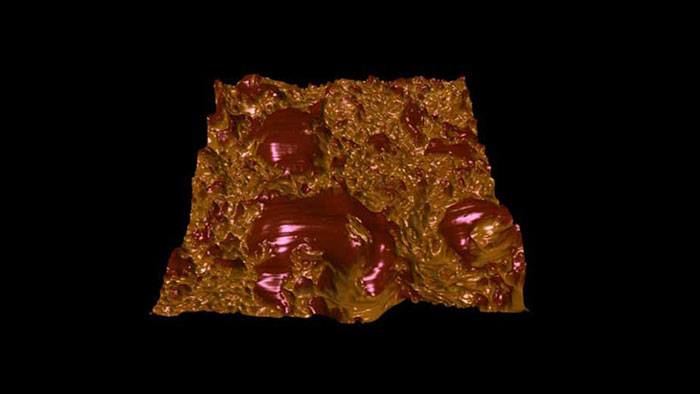

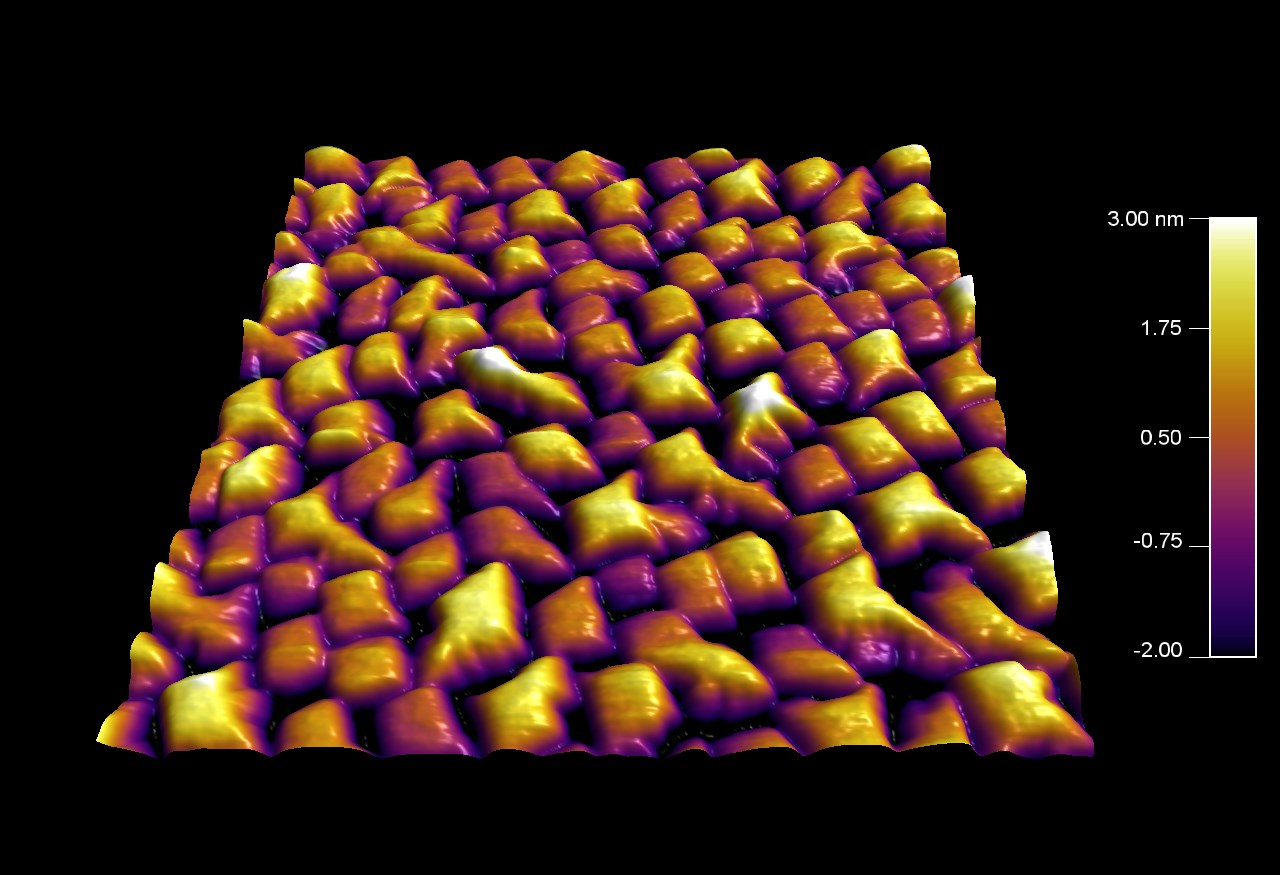

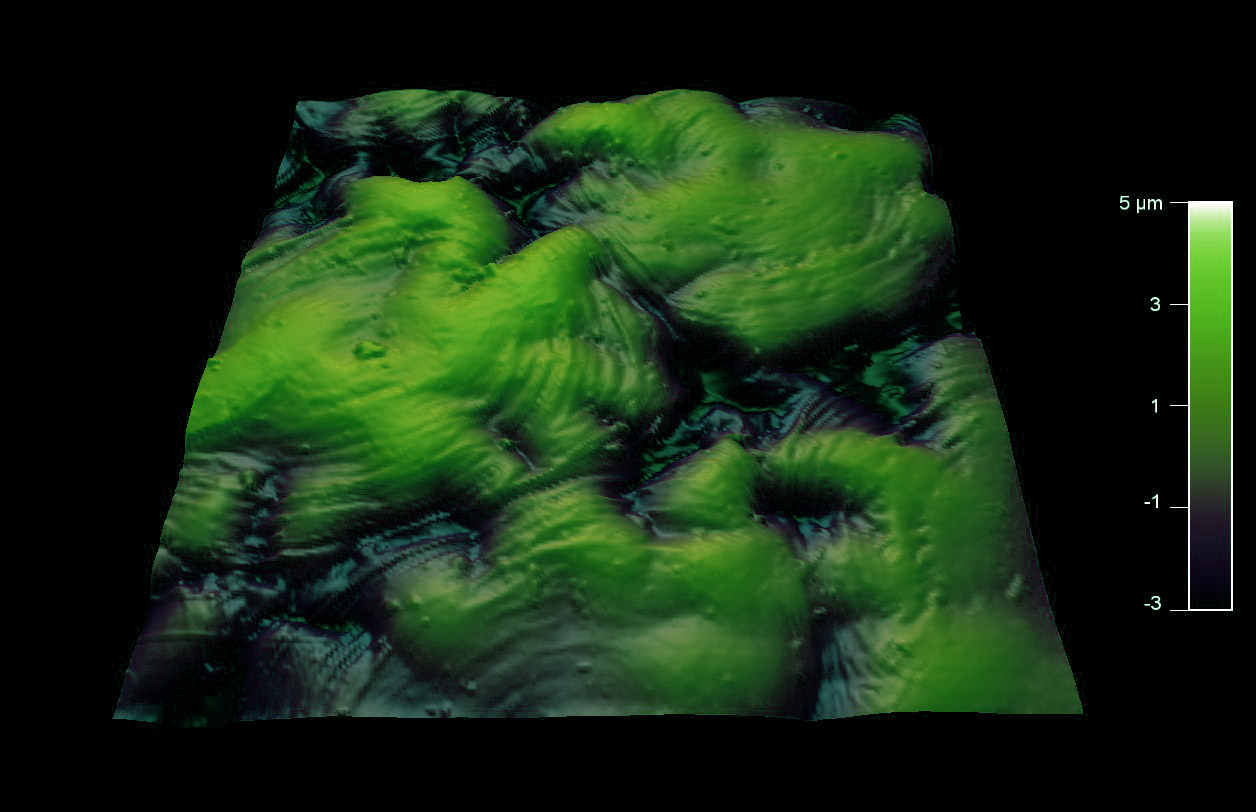

Chocolate is a complex material consisting primarily of a finely crystallized continuous fatty lipid matrix (cocoa butter) in which cocoa powder and sugar particles are dispersed. With time, the lipid crystals tend to merge to form larger crystals on a micron scale, significantly effecting the texture and taste of the chocolate. These images are of an aged commercial dark chocolate sample. The topography of the surface is rendered in 3D, while the coloring is an overlay of the phase image, which highlights the compositional differences (darker patches being the growing cocoa butter crystals).

Scanned with a BudgetSensors Tap300Al-G AFM probe, 15 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

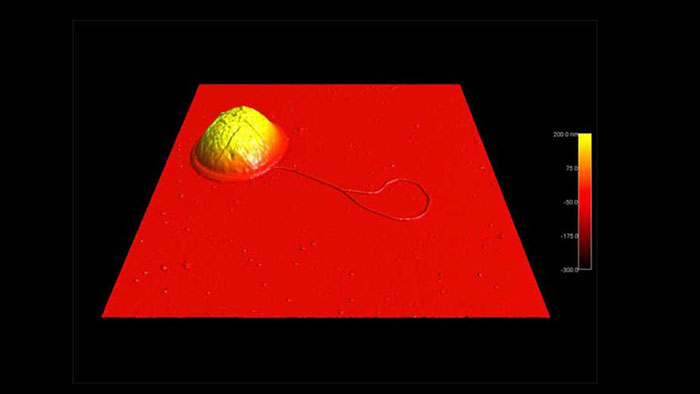

E-coli bacterium with flagellum

Scanned with a BudgetSensors Tap300Al-G AFM probe, 6 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

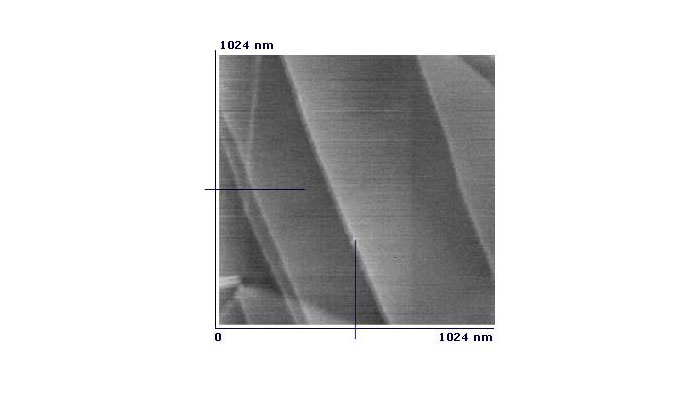

Highly Oriented Pyrolytic Graphite (HOPG) sample

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1024 nanometer scan size

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

Phase image of a styrene-ethylene-butylene-styrene (SEBS) triblock copolymer

Scanned with a BudgetSensors Tap300Al-G AFM probe, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

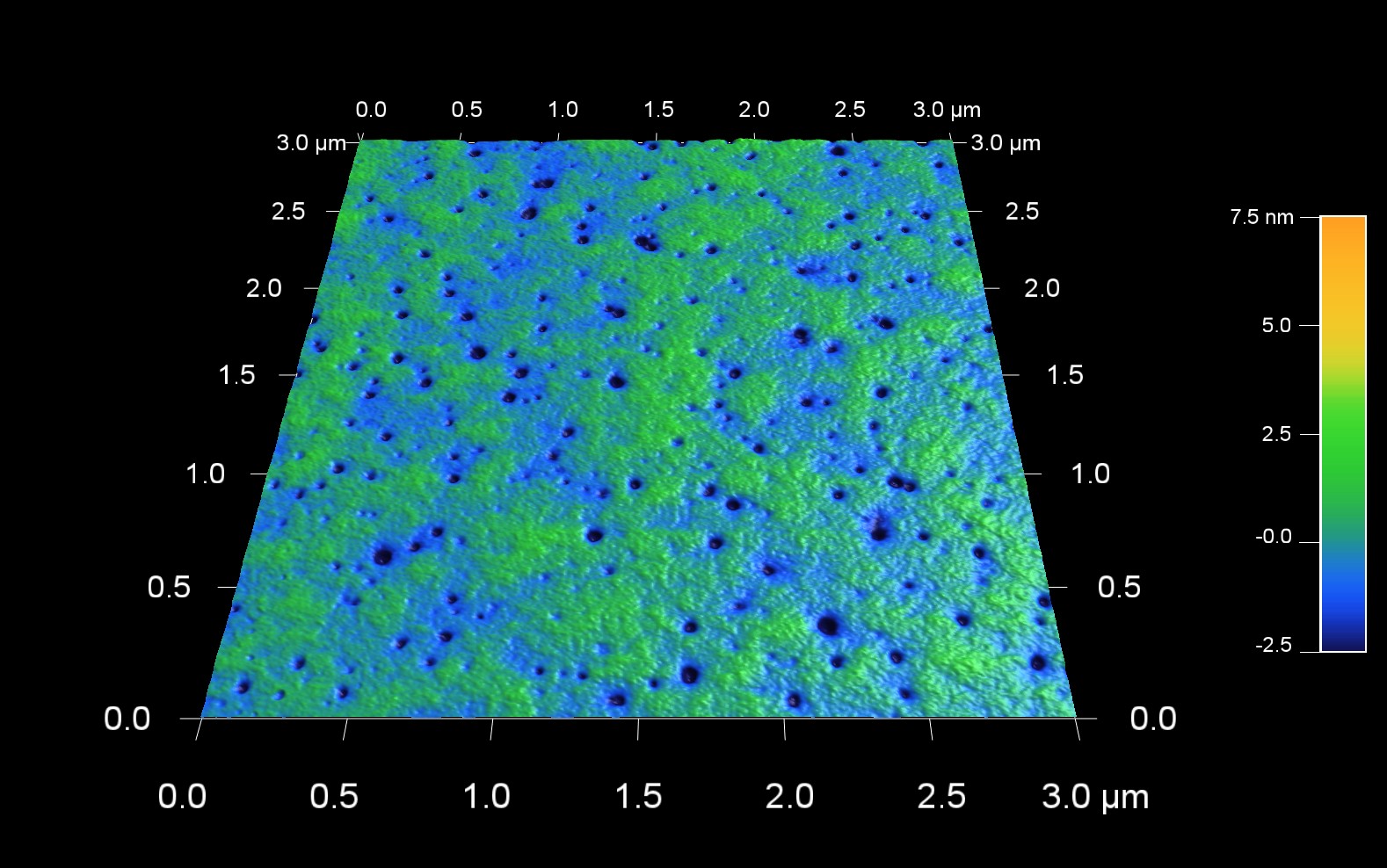

The porous surface of anodized aluminum

Scanned with a BudgetSensors Tap300Al-G AFM probe, 3 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

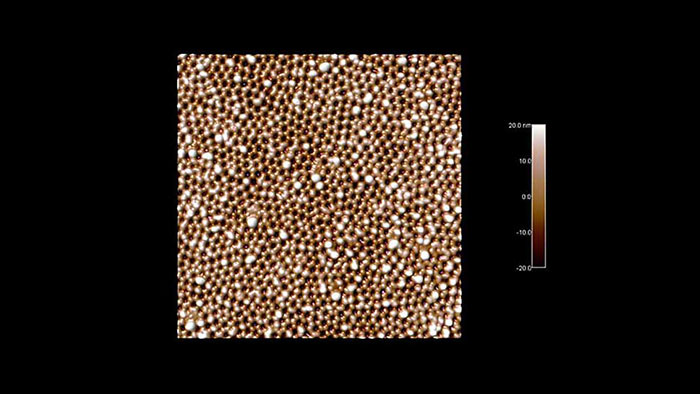

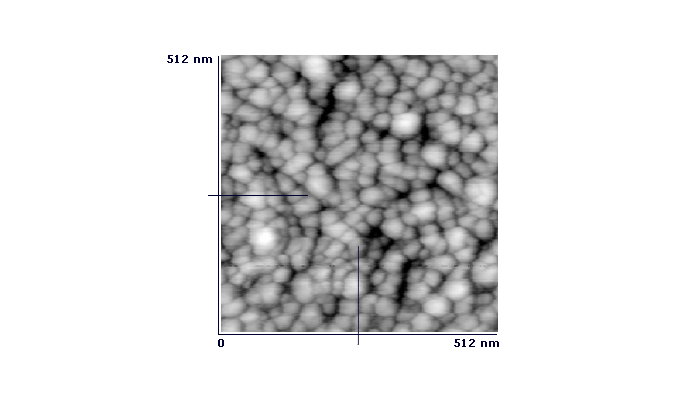

Nanoparticles (20~50nm)

Scanned with a BudgetSensors Tap300Al-G AFM probe. 512 nanometer scan size

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

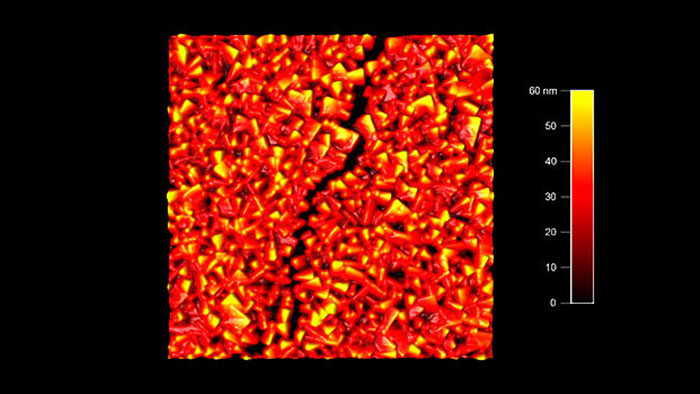

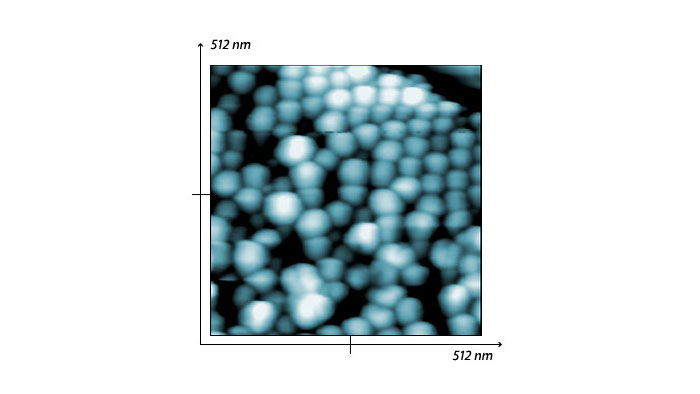

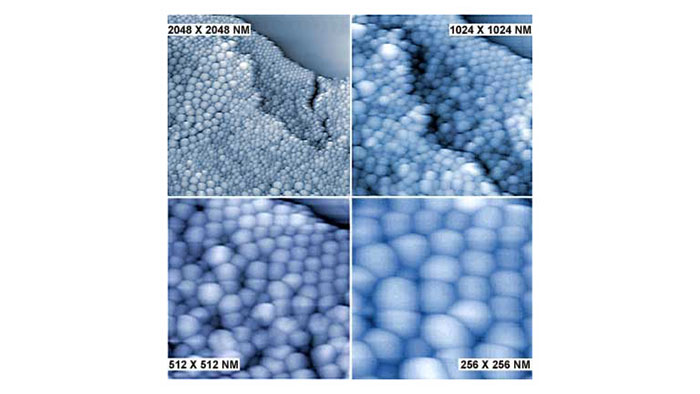

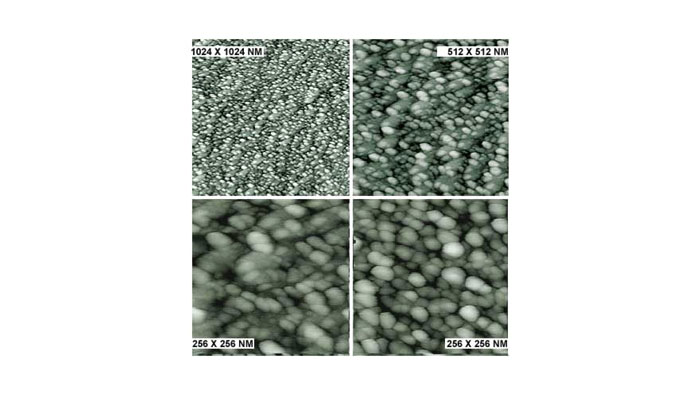

Zinc oxide nanoparticles (20~50nm)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 2048, 1024, 512 and 256 nanometer scan size, respectively

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

ZnO2 sample

Scanned with a BudgetSensors Tap300Al-G AFM probe

Image courtesy of Albert Lin Angsnanotek Co., Ltd., Taiwan

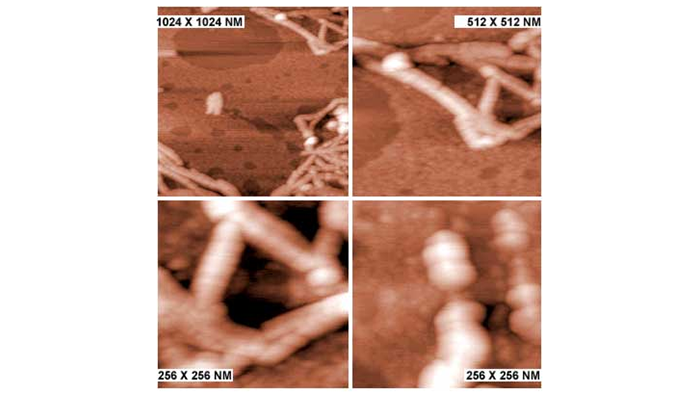

Amyloid fibrils (4~8nm)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1024 down to 256 nanometer scan size

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

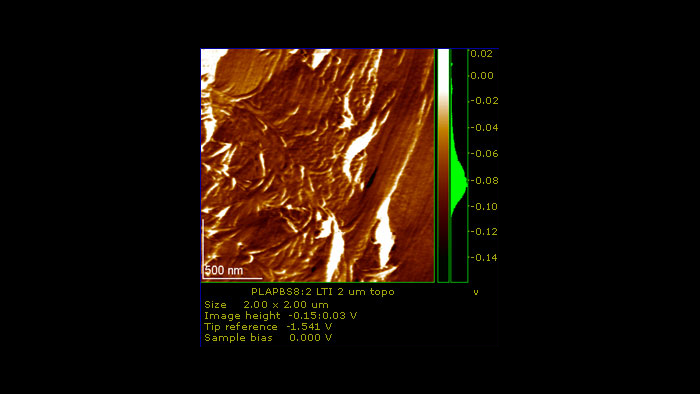

The blend of two biopolymers with compatibilizer

Scanned with a BudgetSensors Tap300Al-G AFM probe, 2 micron scan size

Image courtesy of Nagoya Municipal Industrial Research Institute Japan

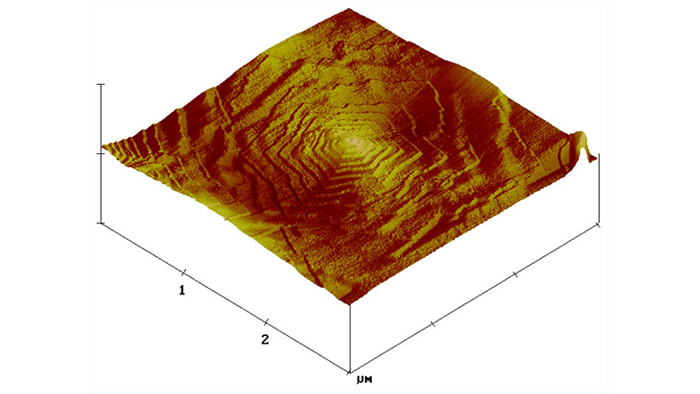

Screw dislocation in poly-oxy-methylene (POM)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 3 micron scan size

Image courtesy of Jeff Kalish, University of Illinois at Urbana-Champaign, USA

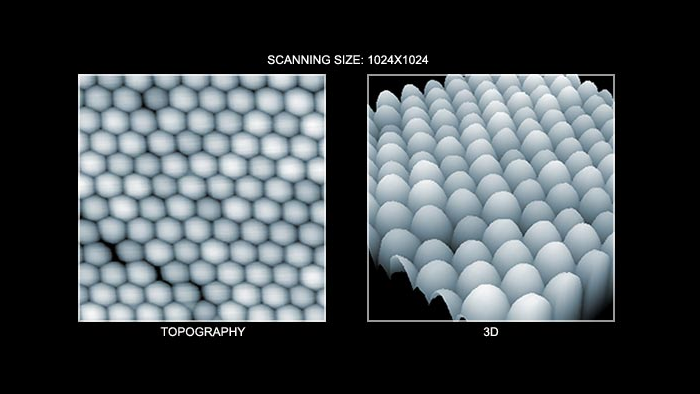

Topography (left) and 3D topography (right) images of nanoparticles

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1024 nanometer scan size.

Image courtesy of Albert Lin Angsnanotek Co., Ltd., Taiwan

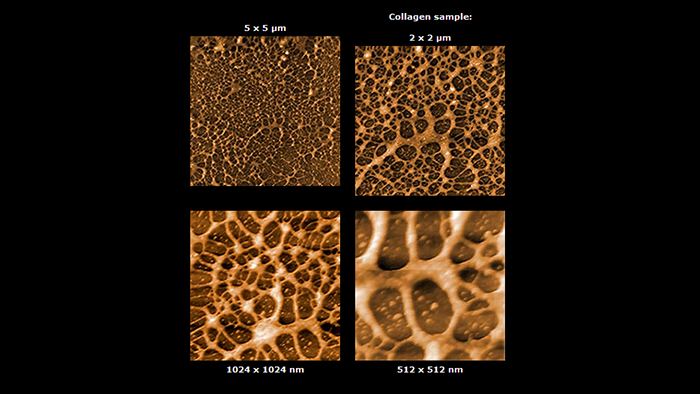

Scanned with a BudgetSensors Tap300Al-G AFM probe. 5000, 2000, 1024 and 512 nanometer scan size, respectively

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

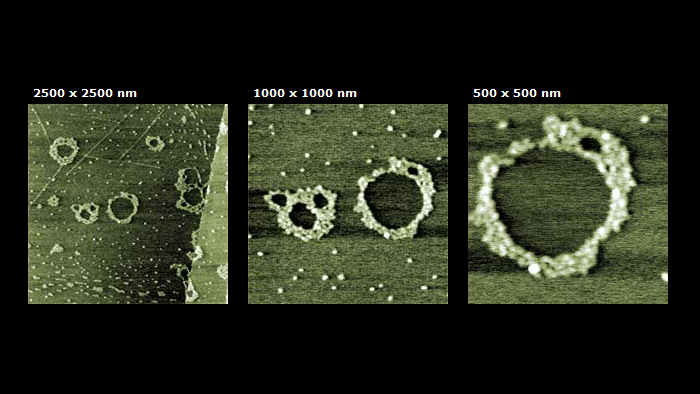

Scanned with a BudgetSensors Tap300Al-G AFM probe. 2500, 1000 and 500 nanometer scan size, respectively

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

Imprints of different porphyrin aggregates in polystyrene

Scanned with a BudgetSensors Tap300Al-G AFM probe, 2.5 micron scan size

Image courtesy of Walter Smith, Haverford College, Haverford, USA

ZnO particles (<10nm)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1024, 512, 256 and 256 nanometer scan sizes, respectively

Image courtesy of Albert Lin, Angsnanotek Co., Ltd., Taiwan

Scanned with a BudgetSensors Tap300Al-G AFM Probe, 2 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

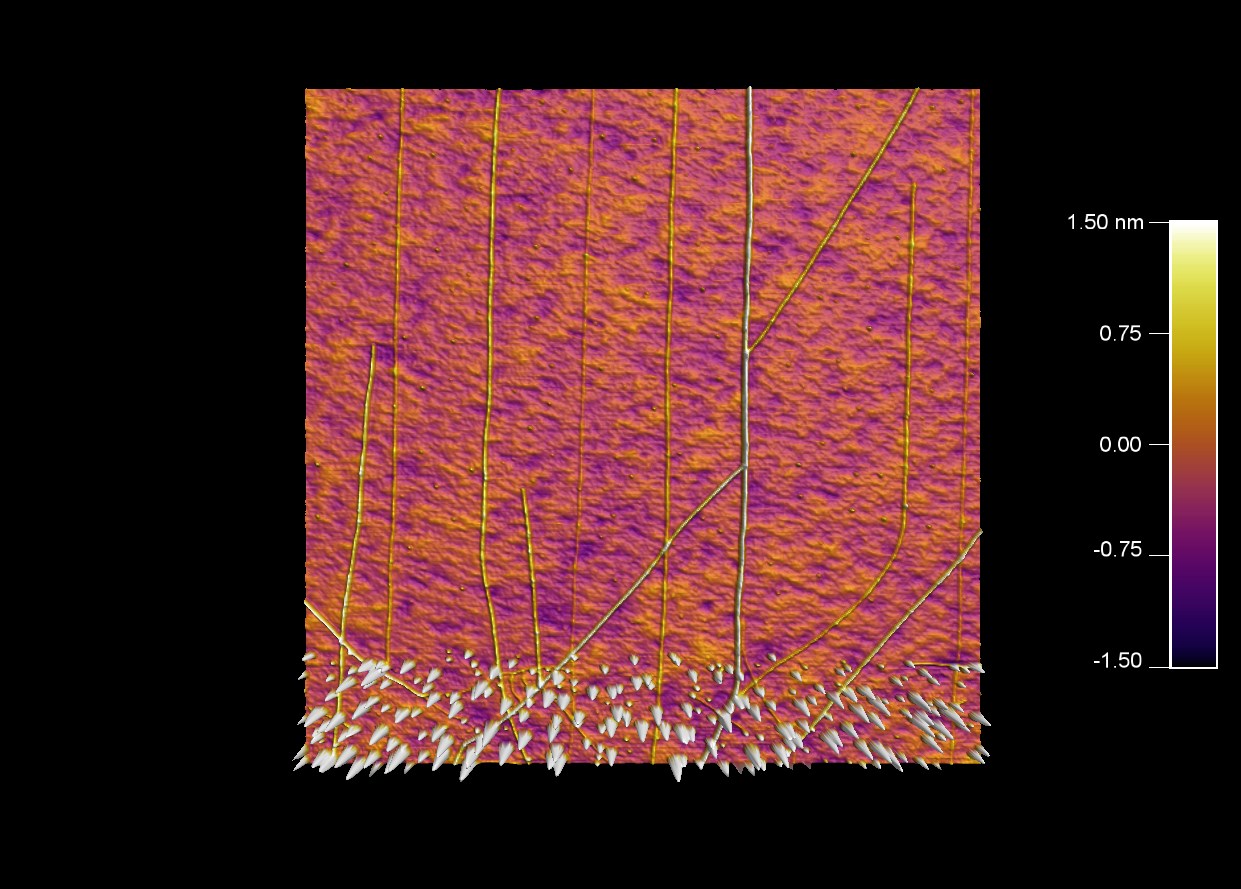

Carbon nanotubes and bundles emerging from line of catalyst particles

Scanned with a BudgetSensors Tap300Al-G AFM probe, 5 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

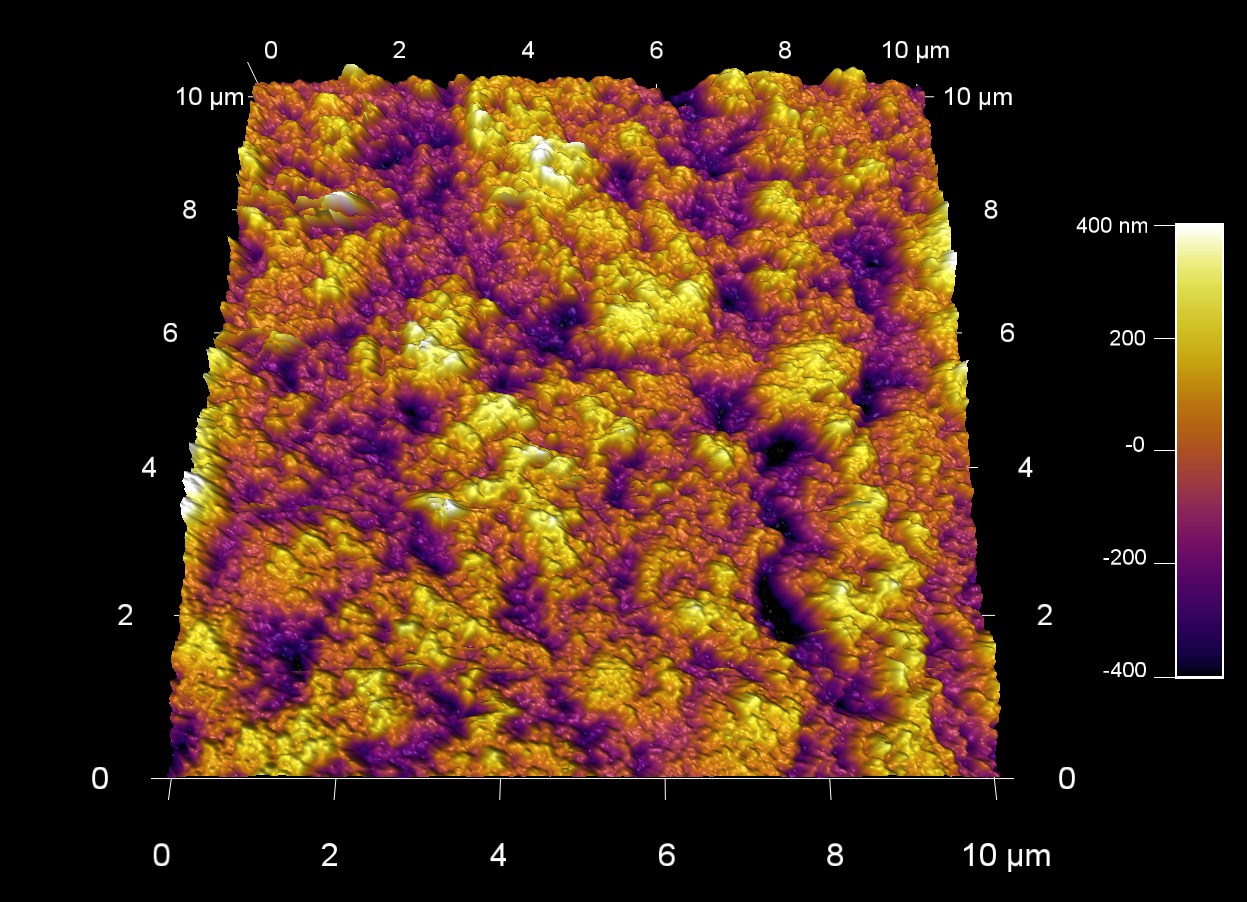

Fast dried white glue.

Scanned with a BudgetSensors Tap300Al-G AFM probe, amplitude image, 10 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 10 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Dendritic growth of HDI polymer

Scanned with a BudgetSensors Tap300Al-G AFM probe, 20 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 10 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 3 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Polystyrene foam surface

Scanned with a BudgetSensors Tap300Al-G AFM probe, 30 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Sesame seed surface

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 10 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Ruptured gold palladium thin film

Scanned with a BudgetSensors Tap300Al-G AFM probe, 5 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

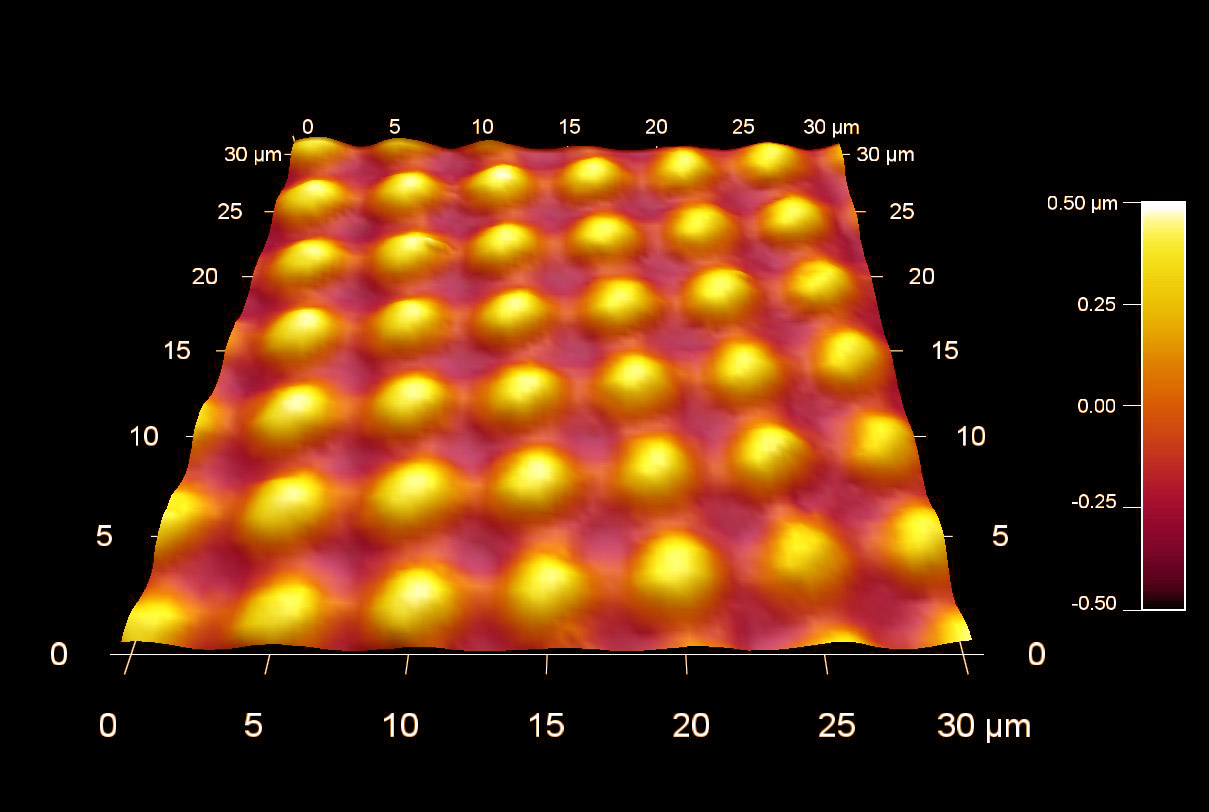

Two dimensional plastic optical grating

Scanned with a BudgetSensors Tap300Al-G AFM probe, 30 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Water etched gypsum crystal

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

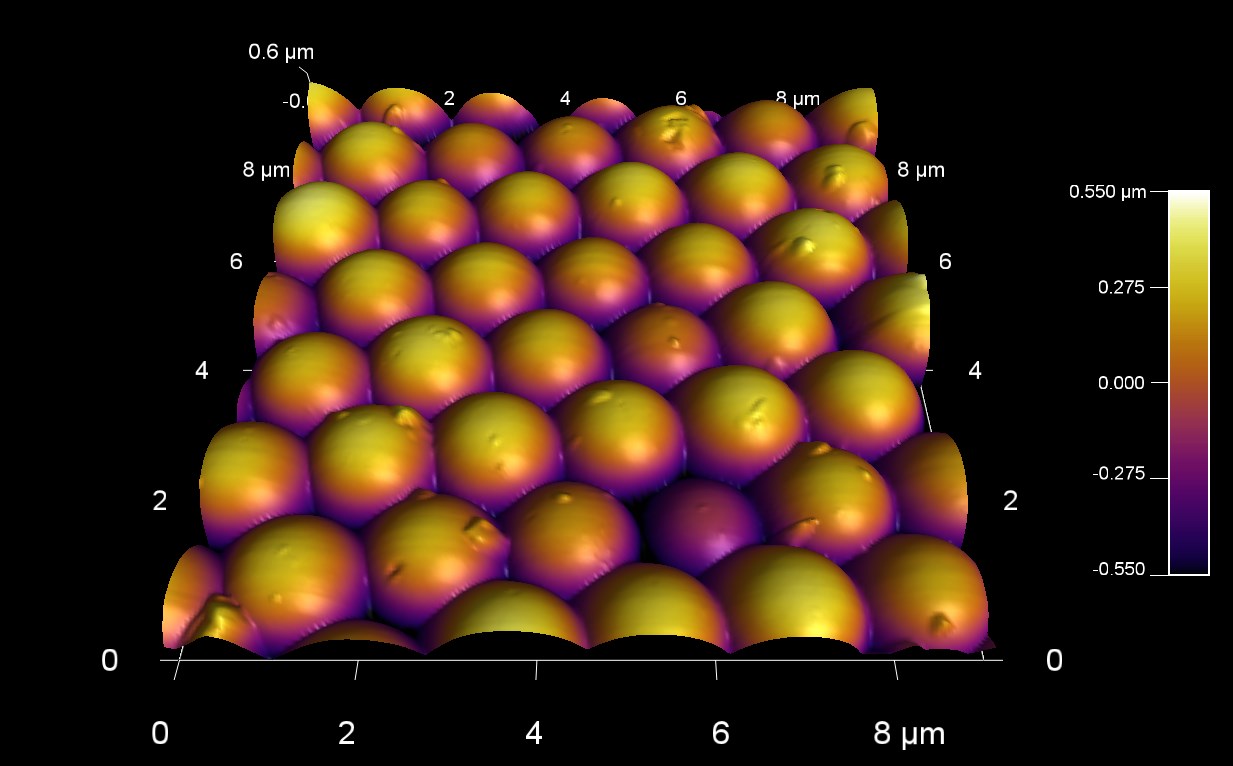

A scan of synthetic opal

Scanned with a BudgetSensors Tap300Al-G AFM probe, 9 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 30 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Polymer blend of polystyrene and polycaprolactone

Scanned with a BudgetSensors Tap300Al-G AFM probe, 10 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 12 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 80 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 70 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

Scanned with a BudgetSensors Tap300Al-G AFM probe, 20 micron scan

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

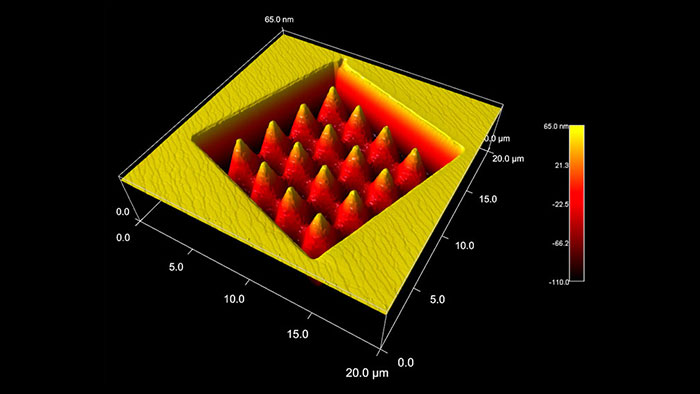

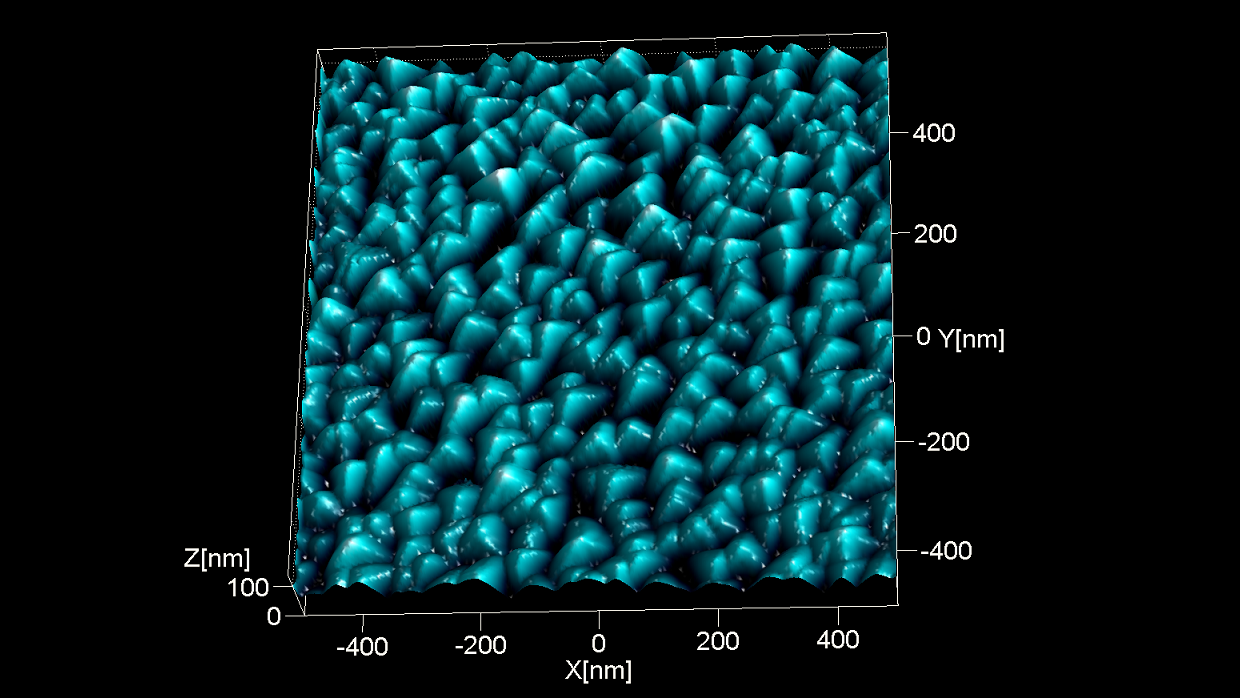

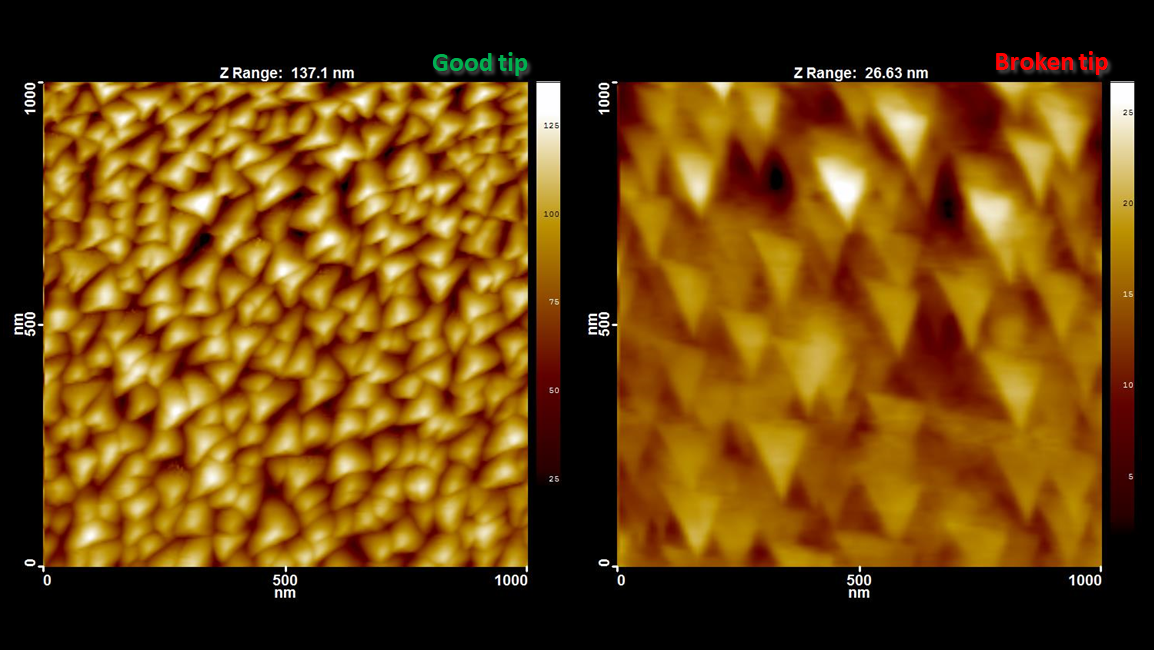

The TipCheck is BudgetSensors AFM probe tip evaluation sample. The sharp pyramidal structures allow reverse imaging of the tip apex.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1 micron scan size

Image courtesy of Dr. Yordan Stefanov, Innovative Solutions Bulgaria

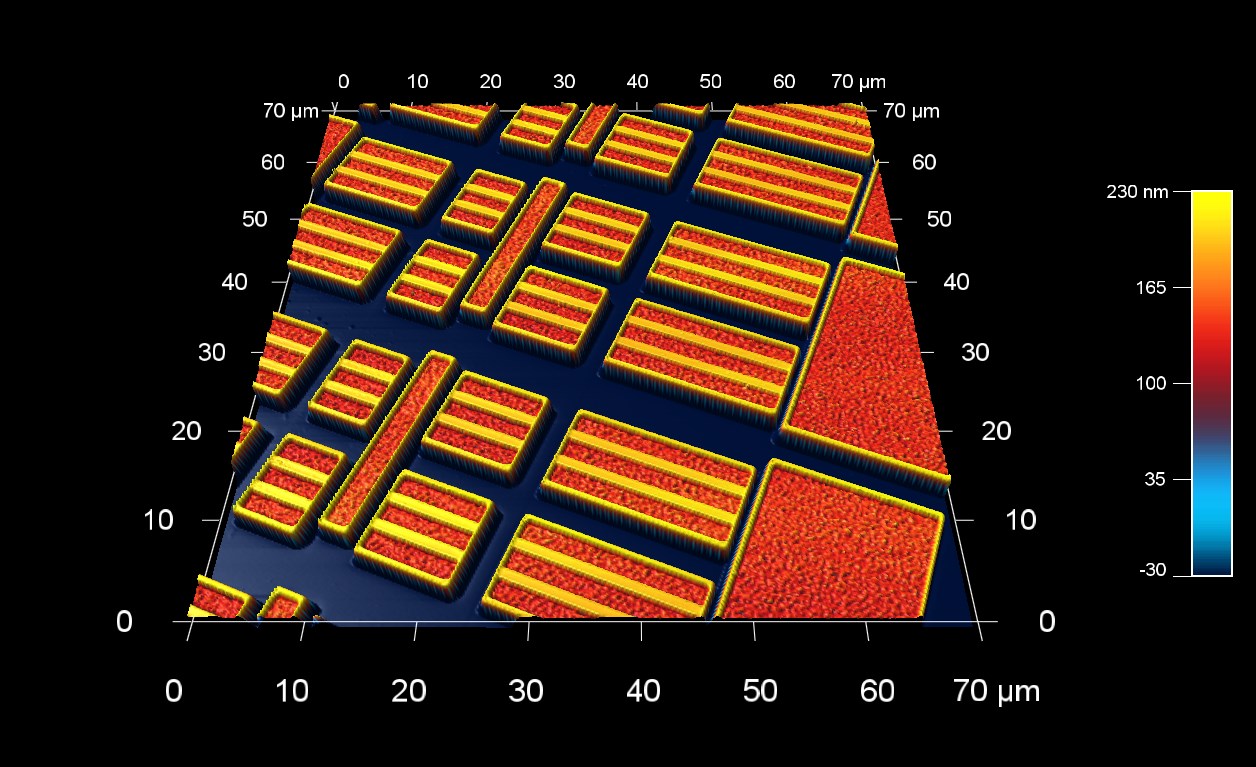

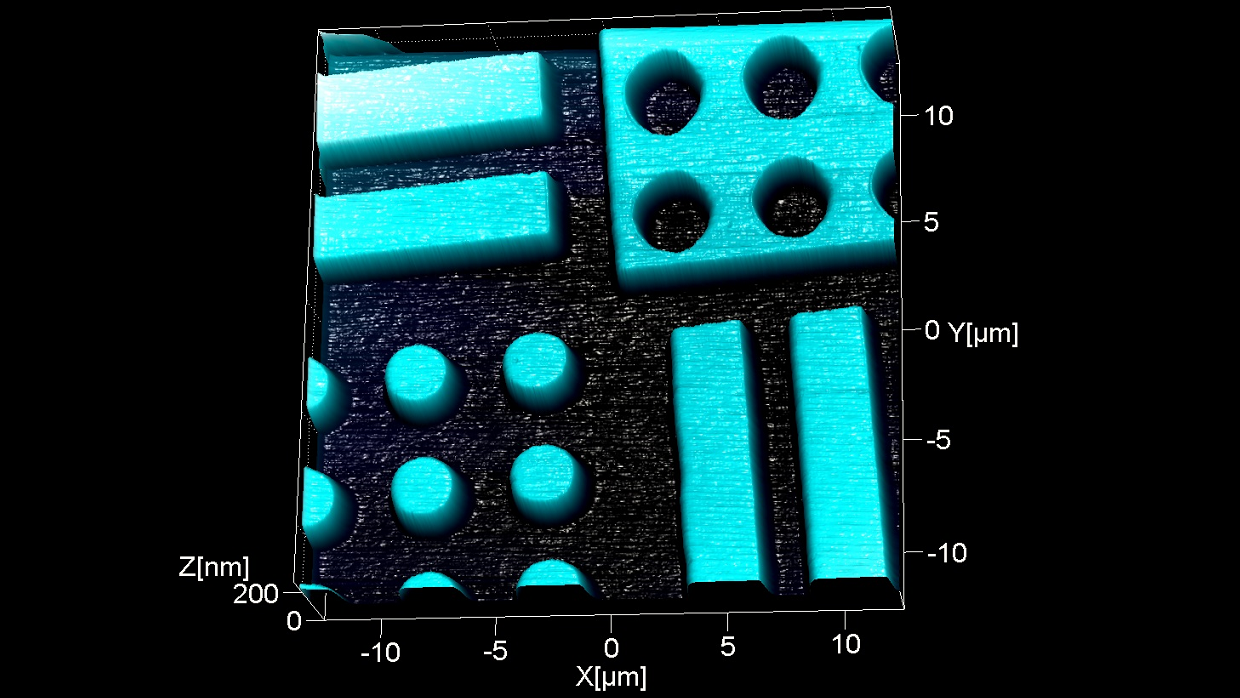

Topography image of the central area of BudgetSensors height calibration standard HS-100MG with 100 nm nominal step height. The HS-100MG can also be used for X-Y calibration of large area scanners. The array design makes it possible to calibrate your AFM system without the need to rotate and realign the sample in-between X and Y axis calibration.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 25 micron scan size

Image courtesy of Dr. Yordan Stefanov, Innovative Solutions Bulgaria

For accurate imaging of small features the AFM tip radius of curvature must be much smaller than the typical feature size. If, on the contrary, the AFM tip is much larger than the features, the result of the measurement is a reverse image of the AFM tip itself! On the left is a tapping mode scan with a brand new sharp AFM probe that reveals nicely the pyramidal structures on the TipCheck. On the right is a scan of the same TipCheck using a damaged AFM tip. The reverse-imaged triangular cross-section of the AFM tip pyramid, broken-off by improper probe handling, can be clearly recognized.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 1 micron scan size

Image courtesy of Dr. Yordan Stefanov, Innovative Solutions Bulgaria

Did you know that collagen is the most abundant protein in our bodies making up around 30% of total protein content?

Scanned with a BudgetSensors Tap300Al-G AFM probe, 40 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

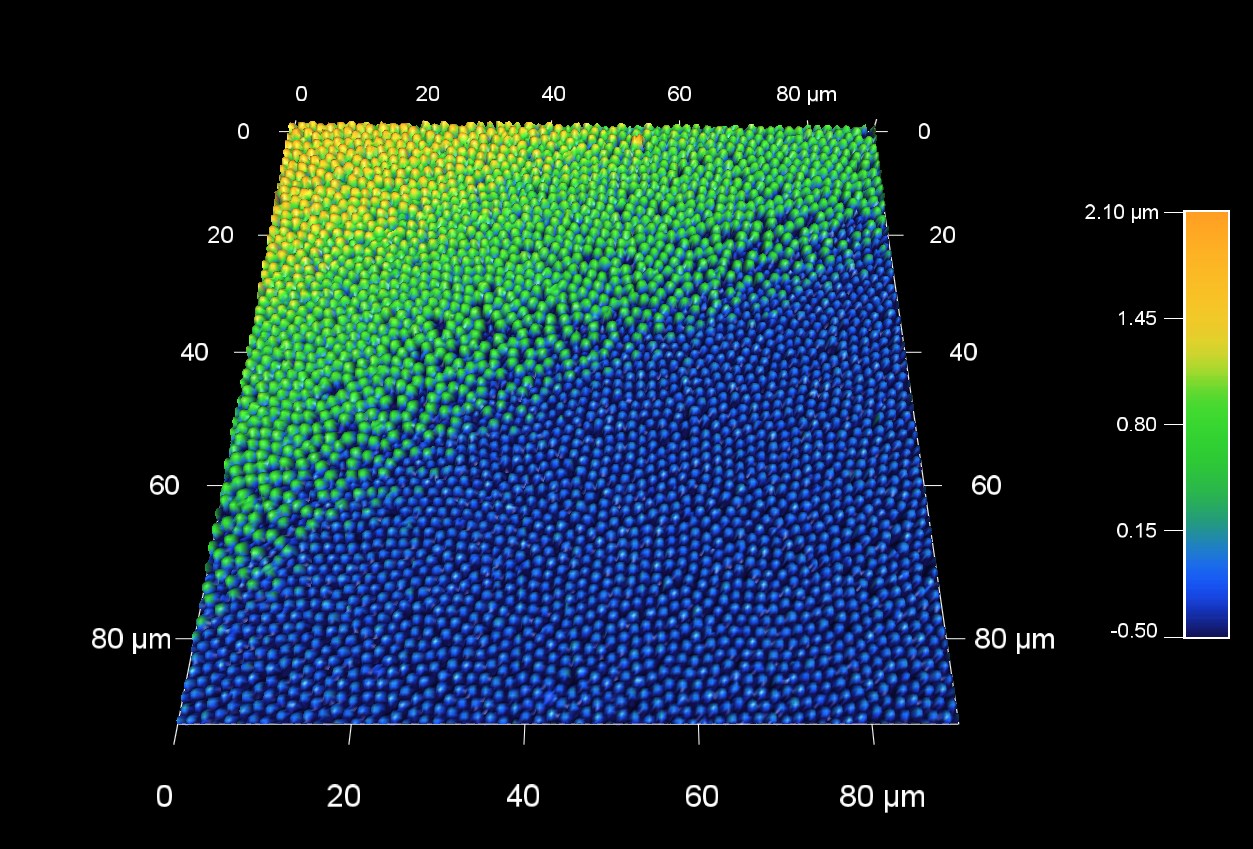

Precious opals are composed of closely packed silica spheres with sizes of several hundred nanometers. The beautiful colors of opals are caused by light diffraction and interference. This 90 micron AFM scan shows an opal surface with two transitions between neighboring planes of nanospheres.

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 micron scan size

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA

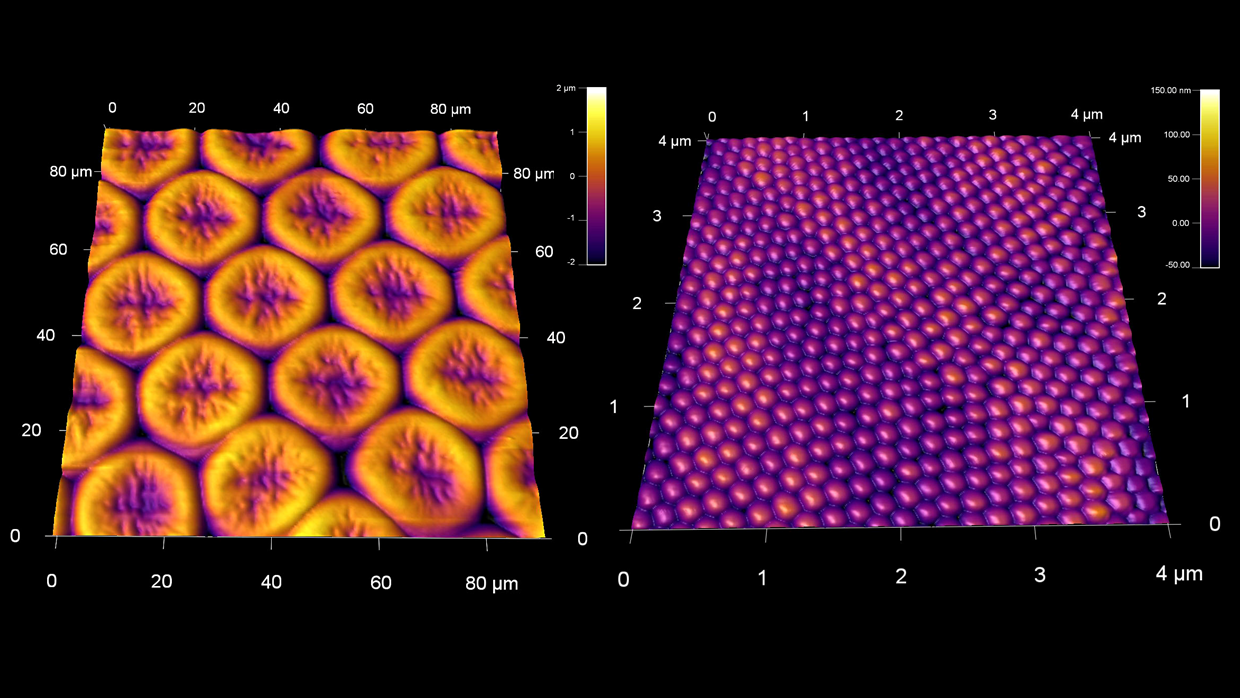

Large scale structure of a desiccated compound butterfly eye (left) and fine nanostructure completely covering the facets (right)

Scanned with a BudgetSensors Tap300Al-G AFM probe, 90 and 4 micron scan size, respectively

Image courtesy of Scott MacLaren, University of Illinois at Urbana-Champaign, USA