Nanoindentation and Lithography AFM Probes

In addition to measuring sample surfaces, an AFM can be used to manipulate or to modify surfaces.

For nanotribology, nanofabrication, nanomachining, hardness measurements by nanoindentation, nanoindentation, nanolithography, and local surface elasticity and viscoelasticity mapping on solid surfaces, an extremely hard AFM tip and an AFM cantilever with a high force constant are required to achieve a high force load.

A hard AFM tip (Diamond, DLC coated, Platinum Silicide, Nitride, EBD) is necessary so that the AFM tip is not destroyed when penetrating the sample or its surface (oxide) and does not wear out too quickly during a dynamic measurement.

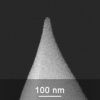

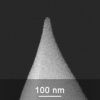

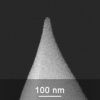

AFM tip shape and contact force determine the penetration depth and contact area in these methods or the structure width in nanolithography by scratching.

In addition to the hardness and shape of the AFM tip, the orientation is also important. A disadvantage of AFM based nanoindentation is the non-perpendicular indenter (probe) approach. Quantitative nanoindentation requires the probe to approach the sample perpendicularly, which is not the case normally for AFMs due to their optical deflection measuring system for the AFM cantilever height movement detection. This problem can be overcome with tip-tilt compensation AFM probes.

The narrower an AFM tip is, the deeper its penetration depth can be, but AFM tips are not infinitely sharp. Therefore, every measurement is a convolution of the actual surface topography and the shape of the AFM tip. A common approach to simplify the determination of AFM tip radius for nanoindentation is to use rounded AFM tips to obtain defined indentation structures for quantitative results and for tribological measurements. The radii of these AFM tips can be easily characterized, as can the mechanical behavior of the cantilever.

Knowledge of the AFM tip shape and behavior of the AFM cantilever also enables data analysis of nanoindentation measurements by modeling the indentation according to the Hertzian model. Oxidic rounded silicon AFM tips, EBD spheres and colloidal AFM probes are recommended for this purpose.

The same AFM tip shapes but with soft AFM cantilevers can be used for local surface elasticity and viscoelasticity mapping on biological samples and friction measurements.

If the AFM tip is also conductive, resistance measurements (SSRM) can be carried out at the same time or modifications to the surface can be made by nanooxidation.

Soft sharp AFM tips and soft AFM cantilevers can be used for mechanically induced nanografting on polymer monolayers or surface-initiated polymerization (SIP) and constructive reversible nanolithography on Self-Assembled-Monolayers (SAM).

For performing microscale scratching and microscale wear applications with AFM, i.e. measurements on samples with extreme height differences in roughness, special AFM probes, the so-called Extra Tall AFM Tips (NanoSensors Special Developments List or SDL), can be used. These AFM tips have with a total height of up to 60 µm compared to 15 µm for the regular AFM tips.

Tip Shape: Standard

Tip Shape: Standard

Tip Shape: Standard

Tip Shape: Standard

Tip Shape: Standard

Tip Shape: Standard

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: various

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: Rotated

Tip Shape: various